By A. Torsvoll, J. Abdollahi, M. Eidem, T. Weltzin, A. Hjelle and S.A. Rasmussen, Statoil; S. Krueger, S. Schwartze, C. Freyer, T. Huynh, and T. Sorheim, Baker Hughes

The world’s first steerable drilling liner system has been successfully field-tested by Statoil and Baker Hughes in the Norwegian sector of the North Sea.

Historically, operators and service companies focused on drilling performance optimization and reducing the time to get from spud to total depth. Parameters such as rate of penetration, reducing non-drilling time and minimizing the overall trip time were targeted for improvement – and certainly continue to be today.

Over time, operators’ growing necessity to enter mature and depleted reservoirs and areas with high pressure variations brought with it more complex operational risks. New approaches were needed that dealt with these challenges safely and economically.

STEERABLE DRILLING LINER

Since the early 1990s, several operators have used casing or liner drilling systems to overcome formation/wellbore stability problems, but with limited functionality. Because the market for these systems was then considered a niche market, development of more versatile systems languished. Improvements in other drilling and formation evaluation techniques and liner hanger technologies paved the way for the steerable drilling liner system.

Baker Hughes and Statoil collaborated in the development of 7-in. (8½-in. hole) and 9 5/8-in. (12¼-in. hole) steerable drilling liner systems. Operators around the world face drilling operational risks when entering the matured field phase. Narrow drilling margins, hole collapse and lost circulation are among the challenges that must be dealt with safely and economically.

Casing while drilling (CwD) and liner while drilling (LwD) are established techniques in this industry. They have proven potential to reduce operational time and to mitigate operational risks when drilling in hazardous formations, such as unstable and/or depleted formations and reservoirs.

Many of the operated fields on the Norwegian Continental Shelf (NCS) have formation instability and/or depletion history. For instance, some high-pressure, high-temperature fields with an initially high reservoir pressure are rapidly depleted in the early production phase. In other fields, formations with varying pore pressures present challenges. The uncertainty of pressures and narrow drilling margins often make well planning and execution a challenge to achieve with proper safety margins.

LwD has been recognized as a promising technology to overcome the challenges when drilling in such environments. Several design concepts have been reviewed based on field requirements.

In some applications, existing CwD techniques might be the solution of choice. However, the majority of reservoir sections are completed with a liner instead of a casing. The reasons could be that CwD does not fit the requirements for drilling subsea wells from a floating rig, or CwD may not apply in deepwater wells because of limited rig load capacity to handle the potentially heavy casing string.

The steerable drilling liner (SDL) system includes standard drill pipe as the inner string to handle drilling torque and tripping of the drilling bottomhole assembly (BHA), a conventional rotary steerable system (Baker Hughes AutoTrak) with full steering and logging capabilities.

PROJECT HISTORY

The project was initiated in late 2006 and completed early 2010. Project phases included:

• Idea generation;

• Feasibility study;

• System and component design;

• Manufacturing and testing;

• Full-scale field tests;

• Offshore deployment on NCS.

Two SDL system sizes have been developed: 7-in. for 8½-in. hole sections and a 9 5/8-in. for 12¼-in. hole sections. Both sizes have been tested on the Baker Hughes Experimental Test Area (BETA) in Tulsa, Okla., according to approved test criteria. The main test objectives were to guarantee that the system specifications and functions were thoroughly qualified before the first offshore piloting at NCS.

In April 2009, the 9 5/8-in. system was implemented on the Brage field, Well 31/4-A-13 A. The 7-in. system was tested in January 2010 on Statfjord B, Well B-25.

COMPONENTS

The SDL is an integrated drilling system that has advantages of both rotary steerable drilling technology and the liner drilling method. It consists of a retrievable and changeable inner string with a pilot BHA and an outer liner string. Inner and outer strings are connected via a running tool that is located at the top of the liner. The liner rotates slowly with 10-40 surface RPM while the reamer bit and pilot BHA/bit rotates with additional 100-135 RPM provided by a modified positive-displacement motor.

As shown in Figure 2, the running (setting) tool provides the mechanical connection between the drill pipe and the liner. It transmits the torque required to rotate the liner and the axial force that is needed for the liner to run in hole or pull out of hole. The running tool is based on conventional equipment with some modifications for this application. It has a hydraulic release mechanism that is ball-activated. It is isolated during drilling to prevent premature release as a result of drilling pressure spikes. It is also possible to release the tool by applying left-hand torque to the tool from surface. The tool can be re-latched downhole after being serviced at surface.

For length compensation between the inner and outer string, a thruster is placed on top of the drilling BHA. The thruster has an increased stroke compared with standard thrusters to enable re-drilling the pilot hole if needed. The created thrust force pushes the landing splines (integral parts of the motor) into a profile inside the liner shoe to define the axial position of the pilot BHA relatively to the liner.

While drilling, the thrust force is adjusted so that it is higher than the WOB transmitted to the pilot and reamer bit to avoid axial movement of the pilot BHA. A position sensor enables monitoring this condition in real time and adjusting the drilling parameters as required. Part of the fail-safe strategy, however, is to avoid axial locking of the inner BHA.

The landing splines are integral parts of the drilling motor, which is based on Baker Hughes’ X-treme technology, which has been modified to provide increased torque capability as the motor is driving both the reamer bit and the pilot BHA, including the bit.

To transmit weight and torque to the reamer bit, the reamer drive sub carries extendable pad elements similar to the steering pads of an AutoTrak steering unit. Those pads provide a reliable connection between the reamer bit and the inner string and can transfer a multiple of the required WOB and TOB. The drilling forces on the reamer bit and drilling dynamics of the pilot BHA are taken by the inner string and not by the liner shoe.

Reamer bit and liner shoe are decoupled while drilling. This allows simplifying the design of the liner shoe, requiring no advanced bearing assembly at the liner shoe to support the reamer bit.

The pad elements of the reamer drive sub are hydraulically actuated and can be switched on and off via downlink from the surface. For fail-safe capacity, the tool deactivates automatically after a preset time if no circulation is present. The tool status, as well as additional information such as the activation pressure, is sent to surface.

A unique feature of the system is the possibility to change the pilot BHA while the liner remains on bottom. This can be performed by deactivating the reamer drive sub and releasing the liner running tool. Subsequently, the inner string can be pulled out of hole while the liner remains on bottom. For reconnection downhole, the inner string is simply RIH until the landing splines detect the target position and the liner running tool relatches. If required, the pilot hole can be worked free by moving the inner string up and down.

The pilot BHA can be configured according to the needs of a particular drilling application. For the first field deployments, a standard AutoTrak X-treme configuration was used, comprising a steering unit, OnTrak for directional, gamma and resistivity measurements, the BCPM for power and communication, and a modular motor to drive the pilot and reamer bit. In addition, a CoPilot sensor sub was placed into the BHA directly below the reamer bit to monitor downhole vibrations and WOB/TOB distribution.

In selecting the pilot bit, the focus was on steerability, durability and hydraulics. To address the steerability needs of 3°/100 ft, the bit was designed with Hughes Christensen’s EZSteer technology, designed specifically for the planned rate of penetration range. This feature also controls pilot bit aggressiveness.

In drilling with reamers and pilot bits, it is important that the pilot bits are not more aggressive than the reamer bits. By controlling the bit aggressiveness, the balance between weight on reamer (WOR) and WOB can be maintained. An overly aggressive pilot bit will translate into excessive WOR and cause pilot string instability.

The pilot bit was designed with five blades, and the hydraulics were optimized for balling applications. The nozzles sizes were chosen to achieve the desired hydraulic horsepower per square inch for the application.

The reamer bit was designed with five blades, similar to the pilot bit. The blades were designed to be thin to provide sufficient junk slot area to evacuate the cuttings generated by both the pilot bit and reamer bit. The reamer bit does not have any nozzles to clean cuttings away but instead is cleaned using the fluid flowing up the annulus.

Reamer balling was a concern due to the low velocity of the annular flow. Placement of the stabilizer below the reamer was optimized using computational fluid dynamics to ensure optimal fluid flow to the reamer. The cutting structure was designed for durability in the targeted formations but also with more aggressiveness than the pilot bit.

LINER-RUNNING TOOL

The hydraulically releasable liner-running tool was modified to make the release mechanism pressure-neutral during drilling. With a conventional setup of the liner-running tool, the pressure loss over drilling BHA components would act to release the liner-running tool, resulting in unintentional release during drilling.

This was solved by including a pressure isolation sleeve inside the liner-running tool to prevent hydraulic pressure from entering the release mechanism. Once the running tool is meant to release, a ball is dropped from surface and lands in the isolation sleeve. The sleeve is then shifted to allow for hydraulic pressure to release the tool as normal.

OPERATIONAL PROCEDURE

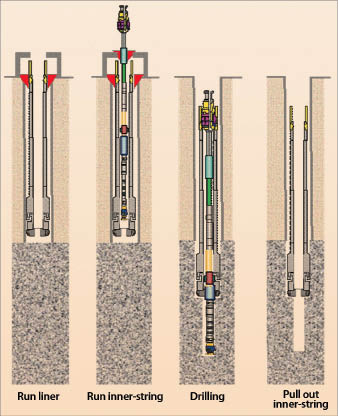

Figure 2 shows the steerable drilling liner system makeup, drill-and-release procedures.

When reaching total depth or in the event of a downhole BHA or inner string failure, the reamer drive sub is deactivated by mud pulse telemetry, and a ball is dropped to hydraulically release the liner-running tool from the liner. Once at surface, the running tool is reconfigured or replaced, and if the POOH is caused by a failed BHA component, the BHA/BHA component can be changed out.

WELL CONTROL

Well control when applying the SDL system is similar to running a liner combined with sand screens as the screens are activated by using an inner string. The system’s established well control procedures are based on:

• Running open-ended liner: Well control equipment is the same as when running a conventional liner. But since there is no float in the liner shoe, closing the annular BOP around the liner is insufficient. A conventional swedge premade to a Kelly cock is made available throughout the process.

• Running BHA and inner string into the liner: A high-performance liner quick-connect (QC) tool was developed as a well control feature for handling a potential live well during the installation of the inner string. During installation of the inner string, the lower half of the QC is placed in rotary. False rotary table is mounted over the QC, and the inner string is run into the liner.

A dedicated QC kick stand is readily available on the drill floor during installation of the inner string. As the ongoing operation is being handled by iron roughneck or rig tongs, the connection of the QC kick stand to the inner string and liner string is done without the need for a casing tong. The inner string is made up to kick stand, and the QC ensures proper connection to the liner. With the kick stand in place, well control can be regained per normal practices.

The QC kick stand includes flow path between the inner string and the inner annulus between inner string and liner. This allows for circulation and bleed-off possibility from the volumes both inside and outside of the inner string.

The QC makes the planned connection of the drill pipe inner string to the liner easy. With the inner string made up to the liner top assembly, this can be connected to the upper liner joint without having to rotate the potentially long and heavy inner string to get a proper connection.

• Drilling: Conventional well control procedures apply as there will only be drill pipe through the BOP.

FULL-SCALE TESTS

Both 9 5/8- and 7-in. steerable drilling liner systems were tested at the BETA in August 2008 and April 2009, respectively, using a medium-size, conventional land rig with full drilling capacity. The tests verified the following: handling and running procedures; system functionality and integrity; and drilling performance and steering capability.

Following the BETA tests, the 9 5/8-in. system was implemented in the 12 ¼-in. section of the Brage Well 31/4-A-13 in July/August 2009. A multidiscipline piloting task group was established to ensure that all aspects of drilling with the system were thoroughly addressed and that lessons learned where included in the planning and execution phase. Drilling logistics and preparation when applying unconventional drilling methods are normally time-consuming, so efforts were made to minimize logistics and handling time.

Because the system includes running an open-ended liner through the BOP (no float in the liner shoe) and when making up the system, having both liner and drill pipe through the BOP simultaneously, special well control procedures apply. Fit-for-purpose procedures and equipment were developed.

The liner was fully centralized by having one centralizer per liner joint. To minimize rig time and handling, all centralizers were mounted onshore.

PILOT EXECUTION, RESULTS

As the planned operation was a world first and as the well trajectory was planned as a 1,170-m horizontal section, risk-reducing measures were applied, such as drilling the first 990 m of the 12 ¼-in. section conventionally and the remaining 180 m of the section with the steerable drilling liner system (Figure 3).

After drilling with a conventional 12 ¼-in. AutoTrak BHA down to 3,873 m, the drilling assembly was pulled out of the hole and replaced with the 9 5/8-in. SDL system, including the 1,228-m, fully centralized liner with specifications (Table 1).

The system had to be reamed down the last 220 m to 3,873 m due to tight hole. Once at total depth, drilling began carefully until full drilling parameters were established. Table 2 compares the average recorded drilling parameters for the conventional drilling (just before total depth of conventional 12 ¼-in. drilling) and the steerable drilling liner system immediately after drilling new formation with the reamer bit.

While drilling, it was experienced that the running tool unintentionally parted, leaving the inner string and the liner downhole. Two separate fishing trips were executed before the inner string and BHA were re-run and reconnected to liner, which, at this stage, had been left stationary downhole for almost five days. It took some effort to free the liner, but after liner rotation and mud circulation were re-established, the well was successfully drilled to 12 ¼-in. section total depth at 4,053.5 m.

After the well was circulated clean, the reamer drive sub was deactivated and the ball was dropped to release the running tool from the liner to POOH the inner string. Running tool release was, however, unsuccessful. Several attempts were executed until the backup mechanical release was achieved. Based on these issues, the running tool design has been modified to prevent these issues from occurring in future applications.

Apart from the issues noted above, the system proved stable as low shock, vibration and stick/slip levels were recorded. Directional control was equal to conventional rotary steerable system drilling.

The 7-in. SDL was successfully tested on Statfjord in January 2010. The section was drilled from 3,000 m MD to 3,181 m MD section TD. The start depth for the SDL was at 3,005 m MD. The first 5 m of the section were drilled with a drill-out assembly to drill the float equipment, the casing shoe and a 5-m rathole. The full 176 m of the section were drilled with the 7-in. SDL. The total liner length was 280 m.

In Run 1, the standard SDL configuration was used to drill the pilot BHA at TD. A SDL standalone service with the BCPM as a master was successfully tested in Run 2. This system setup is a non-steerable BHA option with a very short stick-out of 1.5 m. In Run 2, the liner shoe was drilled down into the reservoir. The liner was successfully set to the designated liner depth and cemented. The new 4 ¾-in. AutoTrak with near-bit gamma performed well in conjunction with the SDL system. The near-bit gamma was needed for geostopping purposes. All test objectives were achieved.

LINER CEMENTING

After reaching TD, the liner was left in the well and the inner string was pulled. With the current system, there is no backflow (float) valve in the shoe and there is no packer in the liner top. First, a cement retainer was run and the cement job was executed, then the liner top packer was run and activated in a separate trip. The cement operation was particularly important in this well, and to minimize introduction of new operations, the cementing operation was performed with conventional tools and procedures. However, the SDL solution includes a time-optimized cement operation where installation of the cement retainer, performing the cement job and setting the liner top packer are done in the same run. This was successfully performed on the Stafjord test.

TORQUE AND DRAG

The measured torque and drag matched the simulated values well on all field tests. For example, the simulated torque of the 9 5/8-in. steerable drilling liner system on Brage was 36 klbf-ft (50 kNm). The average measured value at surface was 34 klbf-ft (47 kNm). Torque and drag of a SDL application with the added weight of the liner is higher than applications with conventional drillstring. For instance, in the Brage case, the torque of the standard rotary steering BHA was 7 klbf-ft lower than the values for the steerable drilling liner BHA. For the Brage application, 6 5/8-in. drill pipe to surface was used to drill the wellbore.

OBSERVED HYDRAULIC, HOLE CLEANING

The hydraulic profile of the annulus can be separated in two main parts and two sub-distributions. The two main hydraulic profiles are: 1) the annulus between open hole/casing and liner – from reamer bit to liner running tool; 2) the annulus between drill pipe and previous casing from the liner-running tool to the surface. The annulus between the liner and the open hole requires less flow rate to clean the borehole (minimum cutting lifting capacity), while the section above the liner-running tool requires higher flow rate due to larger cross-section.

VIBRATIONS

All steerable drilling liner operations were started in pre-drilled ratholes, 8 ½-in.for the 7-in. steerable drilling liner system and 12 ¼-in. rathole for the 9 5/8-in. system. When starting to drill the pilot hole (6- and/or 8 ½-in.) whirl can be expected due to the fact that the pilot BHA is not stabilized within the bigger rathole. As soon the first stabilizer is in the new formation, the pilot BHA will be stabilized and the whirl will be minimized.

In the Brage case, the BHA had to be reamed to bottom. The 6 ¾-in. pilot BHA was not stabilized during the reaming operations in the 12 ¼-in. open hole. These circumstances led to lateral vibrations, with occasional levels of 3 to 4. The total vibration level ranged from 0 to 7. Level 7 is considered the highest total vibration (level 3 to 4 is considered as medium lateral and whirl vibration). Reducing the flow rate to reduce the bit RPM (motor application) helped slightly, but it did not help to run the tools out of specifications. During reaming operations, when the pilot BHA is out of the pilot hole, lateral vibrations can be expected.

DIRECTIONAL SURVEY

Analysis of the raw measurement-while-drilling (MWD) data compared with the post-section gyro logging of the well showed a good match. Having the liner this close to the MWD tool will have a dramatic effect on the magnetic interference; therefore, all surveys were corrected for magnetic interference in real time. However, some movements on the accelerometers were seen indicating that there was some string movement while the survey was taken. This has been rectified for future applications.

RATE OF PENETRATION

The observed ROP was in the same range as conventional drilling. For BETA, it is noted that all wells were drilled in the top-hole section. The average ROP of the last BETA test was 11 m/hr. The average ROP was around 6 m/hr at the Brage well; however, the ROP was controlled to mitigate the operational risk.

The pilot was technically successful; however, the overall operational time was longer than desired. The 9 5/8-in. liner was drilled to total depth and cemented in place, and the issues encountered while drilling make the final results more impressive as several of the steerable drilling liner system’s key functionalities were successfully performed – such as the procedure for pulling and re-running the inner string, reconnecting it downhole and continue drilling – as a result of the failures experienced while drilling.

The cause for the running tool failure has been dealt with, and a redesigned tool will be used in future applications to prevent similar situations to occur.

The main achievements from the 9 5/8-in. system Brage field pilot are:

• The planned interval formation was directionally drilled with the steerable drilling liner system, and the borehole was sealed off by the liner just after being drilled.

• Liner was successfully set at the designed liner depth and cemented.

• The system showed its unique potential of changing the inner string and the pilot BHA while the liner remained downhole. This is applied when reaching TD or in the event of changing BHA components.

• Simulated operational parameters were close to real values.

This article is based on IADC/SPE paper 128685, presented at the 2010 IADC/SPE Drilling Conference and Exhibition in New Orleans, La., 2-4 February.