When it comes to optimizing the wellbore, companies are starting to prioritize factors outside of ROP

While speed remains an important KPI, wellbore placement and quality are now driving more optimization decisions

By Stephen Whitfield, Associate Editor

There are many facets to the complex but essential topic of wellbore optimization. Opinions vary from individual to individual as to what should be the top consideration as companies seek to achieve the optimal profile and trajectory. Is it as simple as rate of penetration? Stability of the wellbore? Durability of the rotary steerable system? The capability to handle high dogleg curve sections? Or is it broader than all of those – asset optimization?

Given the current state of the industry, Marco Perez, Global Drilling Engineering Manager at Weatherford, said he believes the last one – asset optimization – is the most critical right now. This means companies shouldn’t necessarily always push for the fastest drilling speeds; perhaps optimal well placement should take higher priority.

“Everyone is trying to do more with less, so the ability to maximize the asset is extremely important,” he said. “I don’t mean that we need to run the equipment all the way to the point that it fails. I mean that we need to understand how best to use the equipment. We have to understand exactly where we need to go.”

For drilling contractors, too, drilling speed has long been the easiest measuring stick for evaluating performance, but that mentality is starting to change. Todd Benson, Chief Innovation Officer at Helmerich & Payne (H&P), said that his company now sees speed as just one part of the equation. To help operators generate maximum return from the well, it is important to balance economics and other value drivers, like accurate placement in target zone and tortuosity.

“We’re trying to evolve as a drilling contractor through technology developments that allow us not just to drill the fastest well but also to drill one where it needs to be in order to produce the most hydrocarbons,” he explained.

This doesn’t mean that speed is no longer a priority for H&P – it very much is – but it does mean the company is incorporating new and different KPIs into its performance evaluations. “Some customers have received that change pretty well, and there are others who are still looking for us to drill as fast as we can,” Mr Benson said. “The industry’s evolving in that aspect.”

Improving placement

To advance its expertise in wellbore optimization, H&P acquired Magnetic Variation Services (MagVAR) in 2017. The company specializes in survey management platform technologies to help improve wellbore placement. MagVAR’s platform, which launched in 2010, utilizes in-field referencing (IFR) models to provide a three-dimensional model for real-time survey correction.

“We are constantly using our models and our geophysical resources to better our survey accuracy,” Mr Benson said. “We are leveraging the latest magnetic surveys that may occur, either by flyovers or other means, to improve our magnetic model accuracy. We’re adding calculation enhancement so that we can use real-time shape correction software between survey stations to more accurately portray the precise location of the well as we go out to these longer laterals that, generally speaking, have an accumulation in error that increases with depth.”

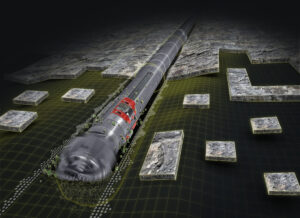

IFR combines independently acquired measurements of the local magnetic field from satellite, ship and airborne sensors to capture the longest to shortest wavelengths in the geomagnetic field in a single model. The MagVAR system presents the data in the form of 3D grids in a software application, then automatically calculates the magnetic declination, dip and total field along any chosen well path.

By combining this with other features, such as multi-station analysis, a significant increase in survey accuracy is accomplished. The company believes this provides greater accuracy compared with earlier methods using lower-resolution, global magnetic models. H&P said that applying IFR and survey management can significantly increase anticollision separation factor (SF) accuracy, or the ratio of well-to-well separation distance over a combined position uncertainty – by as much as 40% in one case study – compared with the main field magnetic models used in standard MWD surveying. This not only reduces collision risk but also enables more accurate well placement.

In another project from 2016, an unnamed operator pad drilling horizontal wells with multiple surface locations on the same pad used the MagVAR system to help optimize wellbore spacing. The ideal lateral spacing for hydrocarbon extraction from the wells was not feasible because the SF was less than 2.0, the level at which collision risk is low enough to allow for safe drilling, at 2,700 ft from the planned well total depth. The MagVAR IFR system improved MWD surveying by providing a more accurate reference direction for azimuth calculation, along with more accurate estimates for magnetic dip angle and total field strength. When combined with MagVAR’s analytics tools, the system increased the SF to greater than 2.0 for the entire length of the lateral, allowing for the well to be drilled to total depth.

Another focus for H&P has been finding ways to leverage automation tools with its survey technology. For instance, the company is adding automated components to H&P’s collision avoidance features, enabling real-time recognition of potential hazards, like a lease line or a well, that may be adjacent to a future planned well. Another development is looking at an automated geosteering system to complement MagVAR’s survey correction capabilities. The goal is to enable real-time adjustment of the wellbore placement through the automated system, thereby maximizing contact with the target hydrocarbon formation.

“Having the automation process all of these aspects in real time and not as something that’s looked at after the fact is really powerful,” Mr Benson said. “The general technology shift is moving from real-time through human influence with a lag of at least minutes and more likely hours to, literally, having something on-site within seconds, having an impact and potentially avoiding things that could be issues in the future.”

Reducing complexity

From a tech developer’s perspective, wellbore optimization begins by having tools that can deliver reliability and consistency, especially as wellbore trajectories become increasingly complex. “We’re no longer just drilling our curves on 8° doglegs, 7,500 ft, and calling it quits,” said Joel Gray, Business Development Manager at D-Tech Rotary Steerable. “We’re seeing lateral lengths increasing and continuing S-curves. This means tortuosity is becoming more and more important.”

D-Tech’s first rotary steerable tool, introduced in 2015, has drilled more than 4.7 million ft onshore, including in the Permian Basin. The company claims it is one of the shortest systems on the market – it averages 13 ft in length – thus reducing the risk of getting hung up while moving through extreme doglegs.

Last November, D-Tech commercially launched its next-generation rotary steerable tool, which is based on the original tool but enhanced to better complete the intermediate, curve and lateral in a single run. Lane Magness, VP of Western Hemisphere, said speed and reliability were equally important focal areas during the development process. This meant increasing its maximum speed from 230 RPM to 350 RPM and keeping the number of moving parts within the tool low; like with its original tool, the new tool only has 10 moving parts.

“Historically, when you pull apart a rotary steerable tool and look at every single nut, bolt and screw, you can see just how many pieces are in it. You realize there are a lot of things that can break or come loose, things you may have to replace and repair,” Mr Magness said.

He notes that the next-gen tool has only one core connection, and everything else is compartmentalized. “That simplicity is a positive on the engineering side because you know what you’re working with and you can change things quickly.”

To reduce the possibility of losing the tool in the hole, D-Tech focused on minimizing design weak points. For example, the tool’s collar has no perforations, limiting the material that can penetrate it while downhole, and it used minimal connections to attach the steering head.

The company also focused on maximizing the tool’s torsional strength. “It’s very common now to drill with massive motors that put extreme amounts of torque to the bit, which is great for ROP. However, if that motor stalls out, it can also put an immense amount of torque across what’s below it. We’ve really tried to account for that in the design to reduce overall risks,” Mr Magness said.

So far, the new tool has completed 74 runs with no failures, drilling 453,906 ft over 2,545 hours, with a 94% field reliability rate. D-Tech is also touting a 95% success rate in reaching total depth in one run.

MWD compatibility has also been enhanced with the new tool, allowing virtually any MWD system to send rotary steerable measurements and diagnostics data to the surface in real time. This means directional companies can run any MWD sensor with the tool and have real-time communications downhole. Further, the company is working to increase temperature capabilities for operation in higher downhole temperatures, to 400°F.

The D-Tech next-generation tool recently completed a tangent (8.75-in. hole size) for an unnamed company in the Cotton Valley formation, near the Haynesville/Bossier shale. This was D-Tech’s first run with the company, which had never completed a RSS tool run without a failure caused by shock.

While successfully drilling the tangent and completing the operation in one run, the tool recorded 7,307 shock counts in excess of 100 Gs and 40.59 hours of time with a shock value in excess of 100 Gs. It also drilled 3,554 ft in 71.9 drilling hours, reaching a maximum speed of 350 RPM during the run while keeping the BHA on plan.

Staying on course

On many shale pads today, minimizing collision risk is an important consideration when optimizing the wellbore. “RSS tools are often run in congested areas where there are multiple producing wells nearby,” Weatherford’s Mr Perez explained. “We’re passing very close to other wells, and as we get deeper and deeper in the earth, the uncertainty of the actual wellbore path is increased. If you actually hit a producing well, that could become a very catastrophic event.”

Weatherford’s Magnus RSS, launched in 2018, features a fully rotating bias unit and three independently controlled steering pads, activated by drilling fluid ported through three rotary valves. This independent pad control mechanism allows for greater proportional control, which can reduce micro doglegs and deliver better overall wellbore position – valuable when it comes to ensuring wellbore accuracy, Mr Perez said.

The independent pad control also allows the tool to drill a smooth curve at a given dogleg, which is a unique capability for a fully rotating RSS.

In one project, Weatherford used Magnus to help drill a full curve section with a high dogleg severity (DLS) in a horizontal well in the Permian Basin. The RSS was deployed along with the company’s HEL hostile-environment MWD system in the curve section. The RSS kicked off from vertical at 8,990 ft and worked at surface speeds from 30 to 40 RPM, downhole speeds of up to 200 RPM and penetration rates of up to 100 ft/hr. It achieved a maximum dogleg severity of 9.89°/100 ft at the bottom of the curve section, well above the planned DLS of 9°.

Because wellbore complexity continues to increase, operators require borehole deviation with precise DLS, Mr Perez explained. “We need to measure, we need to execute, and we need to make sure we’re following the path we set out. The RSS tool must be able to deliver the doglegs,” Mr Perez said, adding that ROP remains important, as well.

In another project, Weatherford deployed a BHA that included the Magnus tool and the RipTide reamer to drill and enlarge the 8 ½ x 9 ½-in. section of a well in Villahermosa, Mexico. The RSS tool achieved an ROP of 40 ft/hr, 35% faster than the planned ROP of 29 ft/hr. It drilled 5,367 ft over 208 circulating hours, without any nonproductive time, until reaching total depth at 13,741 ft.

By eliminating the need for separate drilling and reaming runs, the tools saved the operator two days of rig time. The combined technologies also achieved the planned trajectory of 2.0°/100 ft while keeping DLS below 3.0°/100 ft.

Weatherford has made several changes to the Magnus system since its launch, including the introduction of a downhole turbine generator to power the system using just lithium batteries. DC