Opportunities to lower costs will abound if service companies are engaged at design phase, allowed to leverage expertise

Substantive cost reductions also require changes to traditional procurement-driven model, adoption of integrated approach

By Linda Hsieh, Managing Editor, and Kelli Ainsworth, Editorial Coordinator

Guy Arrington is President of M-I SWACO, a Schlumberger company.

What are some of the particular challenges for the industry as we continue to face low oil prices?

We did not need the decline in oil prices to know that the E&P companies’ investments were growing faster than commodity prices. There was no way that rate of investment could continue, and something had to change. All the downturn did was provide the push for all of us to move more quickly to confront this issue, so that’s what we’re doing now.

The biggest challenge today is addressing the cost concerns for operators and ourselves. The profitability of the industry as a whole, and the service companies in particular, depends on the way we work together, adopt new technologies, learn from other industries and align our technical and commercial interests.

How is M-I SWACO working to reduce costs?

At Schlumberger, we’re thinking about the long term. The downturn has provided impetus to accelerate our transformation program. It is a way that we are looking at delivering step-changes in efficiency, reliability, technology and integration. This means changing the way that we work together to deliver what our customers need.

The first piece of the program focused on our research and engineering (R&E) system to streamline processes and improve reliability. In the near term, this has allowed us to be more efficient and get more new technologies into the marketplace in a shorter amount of time.

Another aspect of the transformation program is multi-skilling, which means training our people to deliver more than one service on the wellsite. This takes people off the wellsite, which enables our customers to lower HSE risks. We need our customers to engage with us in these kind of changes because this can mean changes to their workflows at the wellsite.

What changes to the industry’s business model can help both operators and service providers lower their costs?

We would like our customers to engage with us, not just in the execution of the projects but also in the planning. If they involve us earlier, we can help to optimize the execution by leveraging our technologies at the design phase to eliminate certain challenges. There are innumerable opportunities when we get involved earlier to bring design changes into the drilling process that can help lower costs, especially when we have our Integrated Drilling Services business as part of the equation. That’s when we deliver the most savings.

We’re also willing to look at different business models to align with the way that our customers measure success. It would be helpful to have those conversations earlier in the process to understand what success means to our customers, and then we would like to work with KPIs that they view as indicators of success. In conjunction with that, the business model should be built around those kinds of KPIs so that we’re rewarded for delivering significant cost savings.

What challenges do you see in getting to the table earlier?

Traditionally, the well design is done by the customer, who splits the scope into discrete parts for procurement. The assumption is that securing the lowest price for each part will lead to the lowest overall project cost. Alternatively, we are engaging with customers about the value of our expertise in contributing to the design of a more optimized and integrated system, together with our capability to execute the services. The value created by such collaborations, with a closely aligned commercial model, will far outweigh small variations in supplier prices from the existing procurement-driven contracting model. The challenge is that this is not the way the industry has worked in the past.

So M-I SWACO is focusing on a systems approach?

In Schlumberger we are integrating the design of the downhole system – the fluids, the bottomhole assembly (BHA) and the software to run that entire system – as opposed to putting together individually designed components that the customer might combine from several companies. In the future, new drilling rig designs will be part of the Schlumberger integrated system, and integrating the system design allows us to deliver higher reliability and efficiency.

We also have technology integration centers where our experts work to identify and evaluate opportunities to employ the drilling technologies that we have. Ultimately, our goal is to provide integrated solutions that deliver bigger savings.

Do you find that your customers have been open to that type of approach?

Many are open to this approach. We can make the case very clearly that we can create more value if we are brought into the planning process much earlier and allowed to highlight modifications to the well design to enable more efficient technology deployment. It’s our job to go to our customers and have those conversations.

An example of this was a collaborative approach to a multiwell development project in the North Sea. As early communication between the operator and our drilling experts was critical to producing a field development plan, a collaborative well planning session was organized. This brought all the decision makers together to optimize the multidisciplinary team’s insight into the target area, facilitate well planning, focusing on key workflows and landing strategies. This improved understanding of geological requirements and drilling risks, leading to two new developmental phases.

Can early engagement and integrated solutions help operators achieve the 20-30% reduction in costs needed in deepwater markets?

Yes, they can. Technology and reliability in deepwater are key to achieve further cost reductions. For example, on a high-pressure, high-temperature deepwater well in West Africa, an operator was looking for a drilling fluid system that would maintain flat rheology while achieving exceptional hole cleaning. We selected our next-generation RHELIANT PLUS drilling fluid system, which answered these challenges while also helping to optimize the overall drilling efficiency, including casing and cementing operations.

Experienced and competent people also deliver cost savings in deepwater operations. We have deepwater certification programs where candidates undergo multi-module training and competency testing. They then face a rigorous certification board review of deepwater experts who evaluate their skills, experience and ability to react to different situations before we deem them deepwater-certified. This kind of capability, in addition to early planning engagement, will drive problems out of the system and deliver savings to the customer.

What are the challenges to better data management and use at the wellsite?

An incredible amount of information is acquired at the wellsite, but a lack of integration means this information is captured in applications, tools and sensors that aren’t usually interoperable. The data is compartmentalized in different sources, so our customers spend time doing manual analyses and interpretation. There are normally many service companies working alongside each other. These companies cooperating to share data isn’t something that happens routinely.

Schlumberger is evolving the drilling system from a combination of elements designed separately to an interoperable system with all components designed concurrently. We now design the BHA components together while taking into consideration the impact of drilling fluids and solids control on the overall system performance. And there is a common software platform and ability to communicate across the system from the surface. This delivers a significant improvement in functionality and system reliability.

During times like these when companies are looking to reduce costs, do you think that pushes them to adopt more emerging technologies like MPD?

Managed pressure drilling (MPD) is specifically focused on lowering drilling costs and making the industry more efficient, so the industry should actually turn to it more. MPD has been gaining momentum over the last few years, and we see its adoption accelerating significantly.

We are also striving to embed MPD technology into existing rigs. When customers have this technology embedded on the rig, a large-scale mobilization is not required when they need to apply the MPD service. We support with the MPD expertise and experienced people to run the service. We call this model @balance Rig, which we’re implementing for our Schlumberger land rig fleet. We’re also working with our drilling contractor customers to find economical ways to deploy this kind of approach.

MPD is also conducive to performance-based contracting. We feel strongly about that because we know we can bring significant value. When activity levels are high, we do not always see interest in performance-based contracts, but now is a good opportunity to use this contractual model to improve the adoption of the technology.

What types of R&D projects do you see continuing in this market, and what are the ones that are being canceled or delayed?

Schlumberger spent $1.2 billion on R&E in 2014. Our position is that we invest in R&E both when times are good and when times are bad. That’s what keeps the technology pipeline full, and technology is what helps us bring value to the customer.

As I mentioned earlier, the first aspect we addressed through the transformation program was R&E. The improved throughput that we’re getting from R&E is of great value to us. Right now in the downturn, that increased throughput allows us to focus on where we see the market returning first.

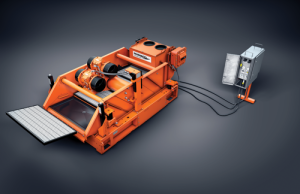

The market will return first on land simply because it’s easier to react and quicker to recover than offshore. In R&E we’re accelerating development of fit-for-purpose technologies for deployment on land. For example, our SCREEN PULSE fluid and cuttings separator, launched in 2015, removes residual drilling fluid from the shale shaker screen surface, thus improving fluid performance while reducing environmental impact.

You’ve talked quite a bit about collaborative innovation. Going forward, how do you think we can make that part of the normal process for this industry?

The first thing that we should do is align objectives between the customer and the service company. If we can be involved early, focus on the same goals, measure success the same way and develop performance-based business models around achieving metrics that define success, then we will be working in the right direction. That’s not always easy to do. It requires a good relationship and lots of conversation and flexibility on both parts.

For me, an important issue is to find a metric other than NPT. The industry often links NPT to a service provider’s performance evaluation and commercial terms. Consequently, we focus on minimizing our NPT. However our NPT is only in the order of 1-2% of total operational time. Although it is always important to minimize the risk of failure, we believe significant gains can be realized by incentivizing service providers to focus on the remaining 99% of operational uptime, so we can further optimize project execution.

A good example of this approach is Statoil’s Mariner project in the North Sea. The commercial model provides for total well delivery– from drilling to production – that maximizes value via the integration of a “one team” approach with a shared understanding of the project’s objectives.

Recently, some of my peers and I sat with one of our top customers to have the discussion around aligning objectives. Topics included “What does success mean to you?” and “What would we be working on if we had our teams sit together to develop a business model and objectives that drove us both in the same direction toward a higher level of drilling efficiency?” This type of early engagement and collaboration will undoubtedly benefit our customers.

What are some KPIs that could be used instead of NPT?

Each customer has different metrics. You can look at the pure cycle time it takes between the start of a well to the start of the next well. That encompasses drilling the well, completing the well, moving the rig and starting the cycle again. That’s the kind of efficiency that matters.

In the drilling world, we should also remember that it’s not good enough just to drill the well – the objective is to improve drilling efficiency. In M-I SWACO, in addition to integrating our MPD services, we contribute added value to our customers by combining our drilling and completions fluid design with optimized solids control, which helps maintain the fluid performance. We aim to assure a high-quality wellbore that allows easy access to and from the reservoir and to optimize placement of the well.

What are some technologies that can be borrowed from outside of our own industry to improve performance?

We pride ourselves on the reliability of our products and services. However, if you look to other industries – for instance, the automobile industry – the metric that we calculated said that if we elevated the performance of oilfield equipment to the level at which the automotive industry operates, it would require decreasing current failure rates by 96%.

That takes a completely new approach to doing things, to designing things and to job execution. We’re focused on all of those elements as a part of our transformation program. We’re focused on designing systems instead of components. We’re focused on automation, which can take variability out of the process. We’re focused on the things we can improve in the equipment, as well as in procedural adherence for the people at the wellsites and our business workflows, and we’re also looking to the other industries for ways to do that.

In our R&E organization, we work with more than 150 technology partners, which add to our global network of innovation around the world. While systems and technology provide the foundation for reliability and efficiency, it’s actually the behavior and actions of people that make a difference. Schlumberger is already an industry leader in procedural adherence. We can still do better by adopting ideas from other industries, such as the challenge and response methodology of aircraft pilot checklists, and by reinforcing procedures across all operations to raise all of them to the same level of performance.

Our transformation program incorporates all of the initiatives we have talked about today, and all of those will help to achieve a step-change in the efficiency, reliability and integration of our technologies, products and services to create value for our customers. DC

RHELIANT PLUS, @balance Rig and SCREEN PULSE are marks of M-I LLC.