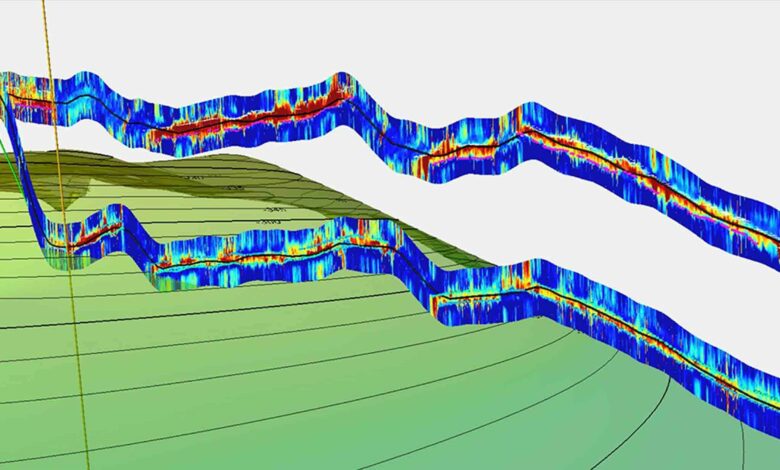

Multilayer mapping-while-drilling service delivers real-time insights to optimize reservoir exposure

Deployments in Australian CSG and offshore China demonstrate service’s ability to provide precise boundary, layer detection for better steering

By Vera Krissetiawati Wibowo and Haifeng Wang, Schlumberger

To overcome structural complexity, poor seismic coverage and technology limitations that can lead to extended drilling time, multiple runs or additional logging, drillers require technology with capabilities to map more than one boundary and accurately estimate reserves in areas of geological uncertainty. Conventional boundary mapping-while-drilling technology with a limited depth of investigation has driven industry demand for technology that improves reservoir identification, enhances decision making while drilling and helps drillers stay in the reservoir as long as possible.

Drillers in Australia and offshore China have doubled the depth of detection range using the PeriScope Edge multilayer mapping-while-drilling service. The service provides deep resistivity measurements, higher resolution and a high-definition inversion process, providing continuity, definition and certainty that improves accuracy of multilayer mapping while drilling.

Multilayer technology

The multilayer mapping-while-drilling service combines advanced inversion with measurements coming from axial, tilted and transverse antenna, which provide faster and higher delineation of reservoir layers and formation evaluation while drilling. The antennas measure resistivity and anisotropy deep into the surrounding formation, providing high-resolution measurements and enabling Rh and Rv mapping of each formation layer, which is supported by end-to-end workflows in a digital environment to work out the accurate multilayer mapping around the wellbore while drilling. The technology has six transmitters with four receivers that operate at three frequencies, enabling complete geosteering multilayer mapping and formation evaluation.

By delivering real-time ultra-high resolution, the service provides precise boundary and layer detection for better steering direction in various reservoir types, including complex thinly bedded and compartmentalized reservoirs. Gamma ray, propagation resistivity and deep directional resistivity measurements provide accurate input for formation evaluation while drilling, helping the operator place the well in the best part of the reservoir and extend reservoir exposure, ultimately improving production. The service reveals up to eight layers and provides mapping beyond a 25-ft radius, delivering accurate geosteering in reservoirs where multiple thin layers could not previously be mapped.

With remote capabilities, the service promotes a digital collaboration for faster decision making while navigating production zones within complex reservoirs.

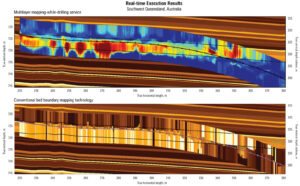

Case study: Australian operator drills long dual-lateral wells within very tight boundaries in unmapped formation

As coal-seam gas (CSG) production continues to increase in Eastern Australia, conventional CSG development methods present multiple geosteering and drilling challenges. A common concept for CSG development includes drilling surface-to-inseam (SIS) wells, but this process consists of drilling horizontal multilaterals to intercept a vertical well and often requires multiple attempts. The horizontal laterals stay in seam to maximize coal-seam exposure. After drilling, water is pumped out of the intercept well, causing gas to come out after the pressure has been reduced. The thin, 1–2-m seams create steering challenges, especially when drillers use low-end reactive geosteering tools. Structural complexities including faults, fractures and coal splits are often not characterized by seismic data, resulting in sidetracks that are especially challenging in coal. Wellbore stability also becomes a challenge when the hole is open a long time for drilling, logging and multiple trips. Drillers must use measurements obtained by crossing the litho-boundary, which requires reactive steering.

In a geologically complex reservoir in southwest Queensland, Australia, an operator faced these and other unique challenges for developing a CSG reservoir. The target formation was at the base of a mountain, and because of restricted mountain access, no seismic shooting was allowed.

The operator planned to drill pilot holes for each dual lateral, but this did not mitigate risks linked with faults and structural uncertainties. The restricted access also prevented the company from drilling a vertical intercept well. Instead, the project required drilling a deviated intercept well and intercepting the deviated wells from both horizontal laterals.

The operator had an objective to drill dual-lateral wells at least 1,000 m within the seam boundaries, where there existed a possibility of encountering faults with unknown throws. The previous conventional approach the operator used in the area consisted of bottomhole assembly (BHA) components including a motor, a bed boundary mapping service, and an integrated measurement-while-drilling (MWD) platform. However, the conventional reservoir mapping-while-drilling technology had a limited depth of investigation of 2–3 m and only mapped one boundary most of the time. Because the area lacked existing wells, the technology limited value for landing and exploring the area.

To improve the depth of detection, the operator used a BHA that included the multilayer mapping-while-drilling service, which detected coal from 4 m away when drilling in the interburden and simultaneously mapped the top and the base of the seam. The BHA also included the ShortPulse integrated MWD platform, which provided direction and inclination and gamma ray measurements, and the PowerDrive Orbit rotary steerable system, which provided near-bit gamma ray, inclination and azimuth.

As a result, the operator achieved the objective of drilling a first dual-lateral well in seam without wellbore stability issues. The technology enabled the operator to navigate back to seams despite several encountered faults. The laterals were 2,200 m long, and the wells landed at 829.5 m and 988 m in seam. The operator intercepted the deviated well successfully in one attempt and ran completions without issues.

In the second dual-lateral well, the operator set the company’s onshore records for the highest extended-reach drilling (ERD) ratio and the longest lateral length from heel to toe. The technology also enabled the operator to drill the longest lateral in the Bowen Basin. The multilayer mapping-while-drilling service helped gather information farther out than originally planned, giving insight for exploring a complex area where doing so was previously considered impossible.

By improving detection range and resolution, the service enabled the operator to efficiently develop the challenging CSG field. Continuous improvements enabled the company to drive down the cost per foot, contributing to significant savings. Overall, the operator improved footage drilled per day by 80% and reduced cost per foot by 31%. As CSG continues to be a significant part of the Australian gas industry, the successful operation presents opportunities for drilling laterals in seam and improving structure mapping and geosteering in CSG fields.

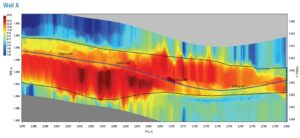

Case study: Doubling the detection range offshore China

An operator drilling two wells in the Chenghai Block in Bohai Bay, China, faced challenges where development wells shift from targeting the center of the sand body to the end. In two previous wells, because of large sedimentary changes and sand body discontinuities, the net-to-gross (NTG) ratios were lower than expected. The average thickness of the sand bodies is approximately 8 m. With previous technology, the depth of investigation was around 2-3 m, making clear depiction of the whole sand body difficult. The rapidly changing reservoir structure made geosteering and staying within the sand body more challenging.

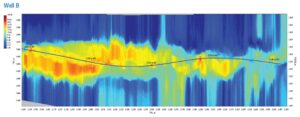

Using the multilayer mapping-while-drilling service, the operator increased the depth of investigation to 6 m, doubling the detection range in the field compared with previous-generation technology. The tool mapped the whole sand body, increased reservoir understanding, and enabled the operator to make informed decisions for maximizing the NTG ratio for each well, thus improving the productivity of the wells. By providing higher-resolution mapping, the service revealed the internal layering and quality variation within the reservoir, optimizing the well path and production.

The PowerDrive Archer high build rate RSS enabled the operator to effectively steer the horizontal section of the wells to handle the abrupt structure changes and target multiple sand bodies in one well. The operator used the multilayer mapping-while-drilling service in well A to map the top of the target sand 2.1 m away and the base of the target sand 5.2 m away as soon as it came out of the casing shoe. The service mapped the top and the base of the sand body throughout the section, clearly showing the pinchout of the sand body. The well was drilled for 256 m inside the sand body, with 50 m/hr average ROP while achieving 100% NTG.

Well B was drilled in an area lacking control wells, causing uncertainties about the thickness and dip of the reservoir structure. At 2,960-m MD, the service mapped the abrupt upward dip change of the base of the current sand body, enabling the operator to build inclination of the well path and avoid drilling out of the current good-quality sand. At 3,030-m MD, the service mapped the top of the sand body and a poor-quality layer at the upper part of the reservoir. The geosteering team dropped the inclination and avoided drilling into the poor-quality zone at the top. At 3,123-m MD, the service inversion showed that the formation dip changed from 0.5° downward to 8.5° upward. The operator called for total depth (TD) based on this information. For this well, the team achieved a 91.5% NTG ratio, drilling 215 m in sand for the total horizontal section of 235 m.

Conclusion

The ability to double the depth of detection range compared with previous bed boundary detection services has helped operators deliver clearer boundary delineation, enabling more precise real-time steering and faster turnaround time. By landing the well more precisely, operators can avoid drilling out to nonproductive sand and reduce costs and risks associated with drilling in complex formations.

Since deployment, the multilayer mapping-while-drilling service has drilled and steered more than 700,000 ft in over 200 runs and 10,000 operating hours. In addition to Australia and China, it has helped operators in the United States, South America and the Middle East place the well in the best part of the reservoir, leading to improved production, reduced cost and risk, and consistent performance. DC

PeriScope Edge, ShortPulse, PowerDrive Orbit and PowerDrive Archer are marks of Schlumberger.