Dual-gradient system ensures quality cement job in North Sea well

OMV uses Riserless Mud Recovery in top hole of Barents Sea well to minimize risks of washout, collapse

By Katie Mazerov, contributing editor

Offshore formations characterized by weakness, shallow-gas hazards, porous sand and other issues present challenges that can result in lost time, cost increases and even the loss of a well. As companies strive to deliver wells efficiently and safely with limited environmental impact, they are looking for technologies that provide real-time monitoring of conditions and help to avert potential well control problems while ensuring wellbore stability.

Since it was first used by a major operator in the Caspian Sea in 2003, Riserless Mud Recovery (RMR) technology has been deployed on more than 200 jobs globally. Developed by AGR Enhanced Drilling, the dual-gradient, closed-loop system facilitates the use of engineered drilling fluid in the top-hole section and returns mud and cuttings to the rig before the marine riser is run, without discharge to the seabed.

RMR was designed with the same principles of its predecessor, AGR’s cuttings transportation system (CTS), which removes cuttings to another part of the seabed rather than to the surface around the wellhead. RMR is best suited for water depths up to 2,000 ft (610 m) but has been deployed in up to 5,000 ft (1,524 m) of water.

In August 2013, OMV used the system to drill the 9 7/8-in. pilot hole and 13 ½-in. section of the Wisting Central well from Ocean Rig’s Leiv Eiriksson semisubmersible to provide a stable wellbore and ensure a good cement job. Additionally, in the unlikely event the producing formation was penetrated during drilling, the hole would be filled with overbalanced mud as opposed to seawater. The producing formation in this area is very shallow, so a good cement job on the 9 5/8-in. casing was critical to provide a barrier between the surface and production zone, explained John Cohen, Research and Development Technology Manager for AGR.

In most cases, RMR is used to tackle problems such as shallow gas and water flow, porous sand formations that take enough water from the drilling fluid to collapse the hole, or weak, highly fractured formations where fluid is lost,” he said.

The system’s mud return feature has added value in environmentally sensitive regions, such as the Sakhalin Islands, the Scott Coral Reef on Western Australia’s continental shelf and offshore Brazil, where conventional methods for drilling top holes are not always advisable, he added. Cuttings are often used to provide samples of the top-hole section, yielding geological information that may not have been available previously.

The technology is designed for top holes, where the first, sometimes two, casing strings must provide a strong well foundation in order for the BOP to latch onto the wellhead. “Most top holes are drilled with the ‘pump and dump’ process, where fluid is pumped down and not recovered,” Mr Cohen said. In some cases, an operator will initially pump using seawater or a very light bentonite mud to clean cuttings from the well.

A heavy mud cut with water while drilling to the desired density also can be used, but that adds logistical complexity at the wellsite. The common practice of “walking the line” to use as little mud as possible to accommodate well pore pressures can result in a mud that is too lightly weighted, further complicating an already problematic formation, he noted.

RMR uses a mud that has been engineered to be properly weighted and with additives designed to respond to particular drilling conditions and improve hole quality, Mr Cohen said. Engineered fluids can, for example, “bridge” the sand, preventing it from taking on fluid. In the case of a fractured formation, the fluid is enhanced with lost-circulation material.

“The system’s closed-loop design provides a lot of efficiency and flexibility,” he continued. “The mud that is pumped downhole is continually returned to the rig, where it is cleaned and reused. The closed-loop system provides volume control so that any influx or loss is known very quickly. In the event of a problem, we can continue pumping without running out of mud. The system, which is monitored by trained, experienced operators using computers on the rig, immediately registers a shallow-gas or water flow, so we can weight-up the mud to hold it back to maintain proper pressure in the well.” In case of instrumentation failure, the pumps can be operated manually while the operation is monitored with cameras.

NCS challenges

OMV used RMR to drill the top hole of the Wisting Central well in the Barents Sea on the Norwegian Continental Shelf (NCS). The goal was to condition the section to optimize the cement job by minimizing the risk of a washout or collapse. The two-day operation, conducted from a fifth-generation semisubmersible in 1,300 ft (398 m) of water, was preceded by pre-job planning and rig preparation that involved some retrofitting to the semi. The rig’s deck also was reinforced with a steel beam. The equipment included:

• Umbilical winch (UW), which raises and lowers the pumps to the seabed and serves as a conduit for power and communication;

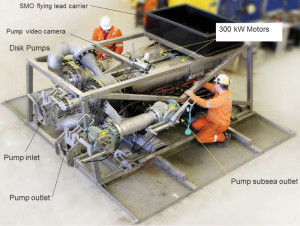

• Suction module (SMO), a large funnel-like device placed on top of the wellhead to collect mud. The SMO is outfitted with video cameras, lights, a pump suction outlet with a ROV-friendly slip-on flange and a pressure transducer to monitor the height of the drilling fluid;

• Subsea pump module (SPM), which houses the 300-kW electric motors that drive the pumps, pressure compensation equipment, a camera for monitoring the pump, a hydraulic power unit with accumulators to operate the valves, and a fling lead to provide power and communications to the SMO;

• Mud return line (MRL), a soft line deployed and assembled in 15-m sections with couplings on each end. The MRL hangs off the edge of the rig from a hose hang-off platform and returns the mud from the SMO on the seabed to the rig;

• Office tool container with computers used for monitoring;

• Control container that conditions power and uses a variable frequency drive with sinus filters to control the speed of the pumps; and

• The rig ROV, equipped with a camera, is used to connect suction and MRL to the ROV-friendly flanges and monitor key aspects of the operation.

Equipment installation began on 13 August 2013 with deployment of the SPM. “Most of our work can be done offline, so we don’t interfere with other activities on the rig,” Mr Cohen said.

The MRL was lifted and assembled one section at a time until it was located on the seabed. The ROV then connected it to the SPM. The flange SMO was mated to the low wellhead using an adaptor fitted to the bottom. Both internal and external adaptors are available. In this case, an internal adaptor was used. Using an internal adaptor makes adapting a seal to the well easier, but the reduced inside diameter requires the SMO to be retrieved before the casing can be run.

The next day, the SMO was landed onto the wellhead and conductor. The UW auxiliary winch deployed the suction hose connecting the SPM inlet to the SMO outlet slip-on flange. The ROV connected the electric flying lead to the SMO, powering up the lights, cameras and pressure transducer used to monitor the mud/seawater interface in the SMO.

Following a test of the RMR system, the drilling operation began, initially pumping a high-viscosity pill to clean the wellbore. The well was displaced to mud, and drilling began. The operator began drilling the 9 7/8-in. pilot hole, reaching a TD of 2,103 ft (641 m) the following day.

RMR operation

Two flow checks were performed at different times during the drilling operation, one with mud in the hole and one with seawater, to conduct an inflow test. “The use of the open mud cap on the SMO makes flow checks much easier,” Mr Cohen said.

“The mud comes up very close to the top of the SMO, and in the event of a water or gas flow, the RMR instruments detect it earlier and more accurately. With conventional wells, an ROV equipped with a camera and sonar is the only way to see mud coming up over the wellhead. The mud can be difficult to see if it is coming up during the drilling process.”

The opening of the pilot hole to 13 ½ in. was performed without incident, reaching a TD of 2,103 ft the following day. The RMR operator, positioned next to the driller for optimum communication, monitored the operation from computers. To allow the operator to run casing, AGR pulled the RMR equipment out of the hole. Before pulling the equipment, cleaning was accomplished by pumping with the SMP and flushing seawater through, up to the MRL. This was possible because the SMO has an open cap, and seawater can be pulled through the top into the pump suction line.

The RMR operation was completed in two days with no major safety or well control incidents. “The operator was able to meet the objectives in the top-hole section, run the casing and achieve a good cement job,” Mr Cohen said.

RMR and CTS are trademarked terms of AGR Enhanced Drilling.

This article is based on a presentation at the 2014 IADC Dual Gradient Drilling Workshop, 7 April, Madrid, Spain.