Adaptive automation facilitates efficient, safe tripping operations

Stepwise approach may help rig crews gain confidence in using real-time engineering-while-drilling calculations

By Bill Chmela, Nicholas Gibson, Egill Abrahamsen, and Ronny Bergerud, Sekal

Automation consists of the use of control systems to manage processes, reducing the need for human intervention. There has been considerable progress made in automating key tasks on the drill floor (i.e., mechanization) and in providing control of weight on bit and bit rotation, etc, to optimize the rate of penetration.

Within well construction, one specific process that may be well suited to this adaptive automation is the tripping of drill pipe or casing into or out of the well. Tripping operations today are guided by pre-drill analysis to determine safe tripping speeds. They require the driller to react to changing downhole conditions to avoid problems such as swab, surge or hole collapse. When tripping drill pipe or casing, it is important to maintain the hydraulic pressure at all depths within a safe geopressure window defined by the pore pressure, collapse pressure and fracture gradients.

Activities that cause the hydraulic pressure to move outside this window can lead to problems such as formation fracturing (i.e., surge), fluid influx (i.e., swabbing) and/or hole collapse.

This article describes a stepwise approach to partial adaptive automation of the tripping operation. The stepwise approach consists of continuously performing engineering-while-drilling calculations to determine the dynamic hydraulic pressure profile variations within the wellbore at all depths for any driller-induced string motions or pump rates.

Then, these calculations will be used to determine safe operational envelopes for drilling machinery (accelerations, decelerations, rates and velocities). This will help the driller to trip pipe in or out of the well while ensuring that the full wellbore hydraulic pressure profile always stays within the prescribed safe geopressure window based on current conditions. Finally, the automation step will be reached where the operational envelopes guide the automated control of the drilling equipment.

Engineering-while-drilling

Until recently, the capability did not exist to continuously and accurately determine the dynamic changes in hydraulic pressure in real time. Engineering-while-drilling was not possible because the required computing power and algorithms did not exist to solve the complex finite difference equations nor to automatically calibrate the model in real time. These limitations were removed when the International Research Institute of Stavanger developed a single integrated engineering model. The model is built using a complete description of the surface and wellbore system; primary inputs include the current wellbore geometry, mud rheology, bottomhole assembly (BHA) and trajectory. This live model is then driven by a combination of the driller’s actions, current well status and thermodynamic effects and is calibrated in real time. The model links the transient mechanical, thermodynamic and hydraulic effects of the well construction process with each other and uniquely compensates for the not-so-well-defined model parameters through calibration.

This calibrated dynamic model can be used to continuously calculate the expected downhole pressure profile at all depths during the tripping operation. An automated analysis for the current well condition and string depth then determines all combinations of tripping velocities, string accelerations/decelerations, flow rates, pump accelerations/decelerations, string rotation and changes to the rotational speed that would cause the dynamic pressure profile to violate the safe geopressure window and, therefore, put the well into an unsafe condition (causing either well swab or surge).

The system recognizes the current status and applies the related maximum accelerations and velocities to the drilling control system, helping the driller to stay within the safe well tolerances. While this automation system is active, the driller would continue to operate as normal, tripping into or pulling out of the well, with or without circulation, unless a drilling operation were attempted that would drive the hydraulic pressure outside of the geopressure window at some depth. In this scenario, the adaptive automation would activate and prevent the equipment from putting the well in an unsafe physical condition.

This automation technique is analogous to anti-lock braking, or yaw and traction control systems on a modern sports car. The driver or driller, in this case, has complete control of operating the car (or drilling equipment) until the system detects that the attempted actions are leading to an unsafe condition. In the driller’s case, the pipe velocity could automatically be limited if the system determined that the driller’s attempted velocity would cause fracturing of the formation, swabbing of formation fluids into the wellbore or well collapse.

The foundational engineering-while-drilling performed here in real time is similar to the pre-drill engineering calculations that have historically been performed on most wells (hydraulic, torque and drag, thermodynamic). The exception is that the new real-time calculations apply fully dynamic (transient) models. The pre-drill engineering calculations typically apply steady state models to determine the torque, drag, hydraulic pressure and other key operational variables that are expected during the well construction process. They also produce roadmaps that show how these variables are expected to change with depth during the well construction process.

This pre-drill planning has tremendous value in ensuring that the correct equipment is deployed to meet the drilling objectives, to create the initial drilling plan, to ensure that the proposed well plan predicts that the wellbore pressure can safely stay within the geopressure window, and that buckling, hole cleaning and wellbore conditioning have been considered prior to starting operations.

However, the pre-drill planning has very limited use as a guide when actually drilling the well or as a real-time guide for adaptive drilling automation. The pre-drill model is based on a proposed well path that very often is different from the actual well path. The model is based on estimates of frictions, weights, interior pipe diameters, exterior pipe diameters, hole size and mud rheology that may not be well known.

The pre-drill model quickly becomes less relevant as the actual conditions deviate from the plan. In contrast, the capability to perform engineering-while-drilling in real time provides a continuous baseline of expected pit levels, dynamic downhole pressures, expected torque, drag and other variables based on driller actions that are extremely accurate as a result of the calibration to compensate for the more uncertain drilling parameters.

Stepwise approach to automation

This real-time calibrated modeling provides the foundation for the adaptive drilling automation described above. This automation can help to prevent operational errors that may be made on the drill floor because of the limited information available to drive decisions. However, allowing a machine to take some control of the drilling activities requires a leap of faith within a relatively conservative industry. Experience has shown that the move toward drilling automation in the oil and gas industry will occur in steps. A good first step is to allow the rig crews to initially gain confidence in the new workflow by performing engineering-while-drilling calculations in a passive or advisory mode so they can make better drilling decisions without the automation.

Drilling teams today are faced with a wealth of medium- to high-frequency raw data from multiple rig sources that are collected both on the surface and downhole. Decisions based upon this data are often dependent on the experience and intuition of a seasoned driller or drilling team. These decisions can be improved and supported if the drilling team is continuously provided with real-time, dynamic guidelines showing the ideal expected values for all of the recorded data. Virtual sensor outputs can be calculated every second during all well construction activities (e.g., drilling, tripping, breaking gel, circulating, sliding, coring, displacing mud) in real time.

The validity of the modeling is continuously verified by comparing the calculated values with the actual values as recorded by sensors on the rig (e.g., pressure while drilling, hookload, standpipe pressure, surface torque, pit level, etc). It is important to note that these real-time calculations have a foundation in pure engineering principles that have been in use by well planning teams and drilling crews for decades but are now available in real time while drilling.

This first step of passive monitoring allows one to gain confidence in the engineering calculations as a foundation for adaptive control. The calculations also provide valuable input for advanced monitoring of the well construction process to highlight emerging symptoms of issues developing within the wellbore. In this passive mode, the calculations allow the drilling team to perform exception-based monitoring, which is a generally accepted engineering technique to identify conditions that may lead to future problems. Detected deviations between modeled and measured values are able to provide engineers with the earliest possible evidence of deteriorating hole conditions that may lead to stuck pipe, kicks, lost circulation or hole collapse.

Exception-based monitoring has been implemented in other engineering-based industries, such as aerospace, power generation and chemical production. The evidence of deteriorating hole conditions, which is founded upon oil industry standard engineering principles, precedes raw rig site observations by hours or days while providing the engineering support needed to take action and address or avoid problems.

To help address the industry’s conservative nature, detected symptoms based on calibrated engineering calculations performed in real time can assist with confirming the drilling crews’ experience-based gut feel or intuition.

The second step toward full adaptive drilling automation during the tripping operation would be to allow the automated analysis to determine which combinations of fluid rheology, fluid flow rate and pipe velocity would place the well in an unsafe condition (causing swabbing or surge) and to alert the driller that he is approaching such limits. These calculated limits will dynamically change during the operation depending on the current well condition and driller’s actions. After the drilling team gains confidence that this alerting capability improves operational efficiency while preventing surge or swab, they are generally more accepting of the move toward full adaptive drilling automation, where the control system would automatically assist the driller in staying within the calculated boundaries.

The final step for adaptive drilling automation is to allow the automation system to actively assist the driller by dynamically setting the maximum drilling equipment accelerations, rates and velocities to ensure that the full wellbore hydraulic pressure profile stays within the prescribed safe geopressure window based on current conditions. In this automated mode, the accelerations, rates and velocities are limited without human interaction.

Adaptive automation in practice

Each of these steps to drilling automation has been tested on multiple field operations. The initial step of advanced monitoring-based engineering-while-drilling to provide early evidence of impending problems has been proven on dozens of wells and is actively being used in multiple real-time operating centers. The growing confidence in the ability to perform this engineering-while-drilling is laying the foundation for true adaptive drilling automation that responds to the changing conditions in the wellbore.

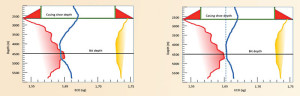

An example of the adaptive engineering-while-drilling system in operation is shown in Figure 1, where the blue line represents the modeled dynamic downhole pressure (ECD) at all depths while tripping out of the well. With the adaptive system disabled, the first graph shows that the pressure has dropped below the pore pressure (seen as the shaded red area), causing formation fluids to be swabbed into the well. With the adaptive system enabled, the adaptive engineering-while-drilling model determines that the attempted actions of the driller would put the well in an unsafe condition and has reduced the pipe acceleration and velocity. The second graph shows the modeled downhole pressure at all depths doing the same operation but with the drilling automation activated. There is no swabbing in this case.

The second example is the use of engineering-while-drilling during a North Sea casing run. Though the geopressure window was wide, the operator was concerned about the effect of fast tripping on the weakest zone in the formation, i.e., just under the casing shoe.

The casing run started at 25 seconds per joint. It was observed that, with this speed, there was a chance of fluid hammering, which could lead to formation fracturing. The modeling shows the downhole ECD reaching 1.95-1.98 sg at this speed. A leak-off test had been previously performed showing a fracture gradient just below the casing shoe of 2.10 sg. The rig was notified that the running speed was causing the ECD to approach the fracture gradient. Immediately, tripping speed was reduced to 35 seconds per joint. This allowed the drilling crew to confidently run casing at a safe speed without the risk of formation fracturing.

Summary

The examples presented here highlight the use of engineering-while-drilling as the foundation for adaptive drilling automation to prevent surge or swab. Similar automated control could be used to ensure efficient cuttings transport, as well as to prevent packoffs, stuck pipe, hole collapse or other drilling problems. Recognizing that the rig crew, who are the consumer for such real-time engineering-while-drilling methodologies, may be conservative in their technology adoption, the authors recommend the cautious stepwise approach, which is:

1. Performing advanced monitoring for early detection of symptoms – making well construction activities safer and more efficient while validating the accuracy of the models;

2. Display operating limits with alarms based on calculation of engineering-while-drilling scenarios in real time to guide operations; and

3. Implementation of the complete adaptive drilling automation for control of the drilling equipment.

This article is based on IADC/SPE 168018, “Safer Tripping Through Drilling Automation,” presented at the 2014 IADC/SPE Drilling Conference, 4-6 March, Fort Worth, Texas.