Drilling & Completion Tech Digest

Keppel deploys smart glasses to improve inspections, equipment monitoring

Keppel Offshore & Marine has implemented 5G Augmented and Virtual Reality (AR/VR) smart glasses at its yard in Singapore.

Equipped with a camera lens, microphone, micro speaker, and cellular or WIFI reception, the smart glasses can perform real-time analyses and provide data to the wearer. The devices also enable the wearer to communicate seamlessly with a receiver or control room. Further, they are equipped with a micro projector, which can project a digital overlay of text and images within the wearer’s field of vision.

The smart glasses are being tested in the following areas:

1. Site inspection, to digitalize the process of inspection and asset maintenance. Inspection personnel can view work instructions via the display headset. This replaces labor-intensive manual check sheets and drawings. Remote expertise and coaching can also be provided via the platform. This application is expected to reduce the manhours required for onsite quality inspection by up to 50%.

2. Digital twin virtualization remote monitoring of equipment performance and onboard system parameters via real-time sensor data. Sensor data can be overlaid on the site engineer’s field of vision, displaying key information such as the equipment’s real-time critical performance and condition during operations. This will also provide a common platform for field engineers and office-based support to troubleshoot and rectify issues. This application aims to improve field engineers’ efficiency by 40%.

3. Remote virtual walkthrough, allowing multiple parties to perform pre-construction feasibility assessments simultaneously, as well as enable potential engineering design issues to be identified earlier, which will mitigate pre-construction risks. It will also facilitate collaboration across different yards where various vessel components are being constructed.

At-bit steerable systems help YPF to drill record-length extended-reach laterals to access million-bbl reservoir in Argentina

YPF recently drilled the first superlaterals pad in an unconventional campaign through Argentina’s Vaca Muerta formation. The BHAs included Schlumberger’s NeoSteer at-bit steerable systems (ABSS), resulting in multiple drilling records for extended-reach laterals that are well past 3,887 m, which enabled access to a 1 million-bbl reserve that would have otherwise been left stranded.

YPF’s goal for the campaign, in the Bandurria Sur Field, comprised several strategies to access reserves while reducing per-barrel development costs. These strategies included drilling superlaterals designed as two-in-one horizontal wells — extended-reach laterals equivalent to two typical horizontal wells by drain length. Doing this required advanced BHA components for improved directional and torque control.

Additionally, YPF looked to adopt best practices and integrated workflows to minimize HSE risks and NPT. The operator believed that implementing these strategies would increase the production rate to accelerate cash flow.

Working together, Schlumberger and YPF agreed on deploying the NeoSteer CL curve and lateral at-bit steerable system to accomplish the aggressive goal. Further, adding the configuration of the PowerDrive vorteX powered rotary steerable system enhanced the downhole energy, enabling higher ROP and rpm rates.

The advanced BHAs allowed YPF to drill the longest geosteered lateral in the basin to 6,866-m TD. It was also the longest lateral in Argentina at 7,190-m TD. Speed records were set, with the NeoSteer ABSS reaching an ROP of 409 m/day, even while building the 6°/30-m curve in a day. In a subsequent well, the ABSS achieved 549-m/day ROP. Both wells were landed at TVD within 3 m.

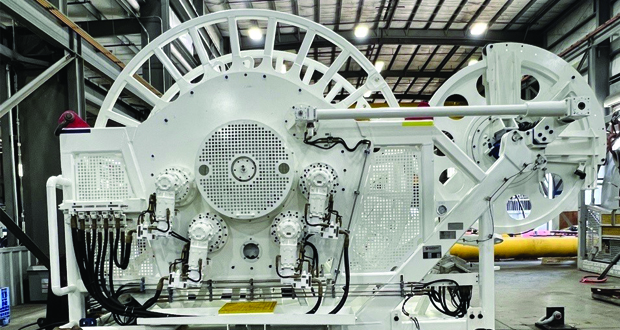

Valaris drillship completes reactivation, begins MPD operation in West Africa

Following reactivation, the VALARIS DS-9 drillship commenced its two-year contract with ExxonMobil offshore Angola in July, embarking on Valaris’ first managed pressure drilling (MPD) operation in West Africa. This achievement was made possible by rigorously following the agreed-upon reactivation strategy among the original equipment manufacturers, third-party support and Valaris. “The decision to preserve the equipment while the rig was positioned in Las Palmas meant that Valaris could swiftly reactivate the MPD system and certify the equipment for operation,” said Shane K. Ritchie, Superintendent of Operations.