Digital drilling system aims to close gap between well plan, rig workflow

To align goals of operator, drilling contractor, service companies, system has been designed to help users adapt to changing conditions with minimal intervention

By Ginger Hildebrand, Schlumberger

Recent advances in drilling techniques have delivered new levels of operational efficiency. Yet, operators continue to strive for even higher levels of drilling performance, with many requesting drilling contractors supply higher levels of automation on their rigs. There is little question about the value of automation – other industries have proven the transformational impact that automation can have on both operations and business models. However, the question remains: How will the drilling industry realize the full potential of automation?

In a market dominated by dayrate contracts and eroding margins, many drilling contractors struggle with finding ways to profitably supply the automation technologies requested by operators. However, the right approach can deliver operational efficiencies that more than offset the investment. Efficiencies are only the most immediate tangible value delivered; other benefits include predictable, consistent results aligned with standard operational procedures and performance standards, and increased safety.

Contractors’ dilemma

When it comes to offering automation, drilling contractors can take several approaches. One way is to combine point solutions from various providers. Each point solution addresses a specific aspect of the drilling process, such as stick/slip mitigation, directional guidance, automated sliding or on-bottom drilling parameter management, aiding the driller in the completion of a task. Point solutions deliver value to discrete operations but are limited in the value they offer due to the need for the driller to integrate and manage them. To transform drilling operations, an automation solution needs a wider scope.

An alternative to point solutions is a process control automation system that helps the driller through post-connection, on-bottom drilling and pre-connection drilling activities. These systems are available from several vendors and include varying degrees of operational flexibility and support for dynamic drilling conditions. Automation systems augment the capabilities provided by a rig’s control system. Because there is no industry-standard control system interface, a rig can only choose an automation solution that the control system vendor has specifically enabled.

Some drilling contractors have developed bespoke automation solutions for their own fleets. Automation development – which requires capabilities related to software, firmware, controls, signal processing, artificial intelligence, IT security, data management, telecommunications and configuration management – is not typically a core competency of a drilling contractor. This approach requires a significant, prolonged investment to develop and support the technology, and this investment is not guaranteed to result in positive returns. An alternative is for the drilling contractor to work with an automation supplier, who can bear the development costs, bring experience and expertise beyond a single fleet of rigs, and amortize the investment over a larger number of rigs.

Beyond the outlay to develop the automation technology itself, there is an investment in each rig to utilize this advanced technology. Each rig’s hardware, software and firmware must be modified to host the technology. Each rig crew has to transition from manual operations to automation-assisted operations. Continually driving toward ever higher levels of performance requires continuous investment in the base technology, as well as its optimal usage.

Drilling is fundamentally a team sport where the operator, drilling contractor and multiple service companies must work together toward a singular goal. After the largest market shock in history, all oil and gas players are under stress. They will have to innovate out of this with technology to deliver operational efficiency, service delivery cost reduction and capital efficiency.

Tackling the problem from only one perspective will not lead to a solution. The industry must find a way to drive performance by incorporating the technical and commercial perspectives of the contractor, service companies and operator. What the industry needs is the integration of the digital and physical, surface operations, and subsurface knowledge, to deliver the next generation in efficiency, safety and performance.

Digital drilling

Most automation solutions focus on the automation and operation of rig equipment to achieve specific tasks. They support the driller in the performance of those tasks but miss the wider view. Drilling automation needs to align with the goals of not just the rig contractor but also the operator if it is to improve overall performance.

Equipment-oriented solutions are tied to a specific vendor’s equipment and focus on equipment operation rather than the process of well construction. These solutions rely on the user to map the operator’s well construction plan onto the system’s capabilities. In most instances, the user does this by consulting a drilling plan, printed on paper, that specifies the operational activities at a high level. Then, they translate those into settings for the automation system. This makes the automation system dependent upon human expertise and sustains the gap between the operator and rig workflow.

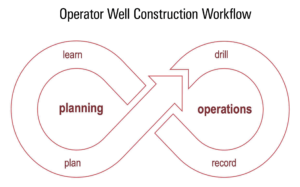

For the last four years, Schlumberger has been developing a holistic digital drilling system. This system (Figure 1) is grounded in the fundamental well construction process – an operator plans a well, then the drilling contractor and service companies drill the well according to that plan. Operational results are recorded, and the operator learns from the results obtained. Those learnings are then fed into the next well, and the loop starts over again.

While drilling contractors typically do not take part in the well planning workflows, it is essential that their rigs integrate seamlessly with the results of their customer’s workflows so that they can deliver the well according to their customer’s specification. Using the DrillOps on-target well delivery solution, the user starts automation with a digital plan, leaving no room for miscommunications or misunderstandings and removing the need for the user to translate the plan into settings for the automation system.

This solution creates a collaboration space around operations that encompasses office roles and rig operations. This automation can be deployed on any AC variable frequency drive (VFD) rig through a rig control system-specific interface. The operator can select other solution elements that it would like to utilize, and they all work together seamlessly. The entire well delivery solution is open through extensibility mechanisms that allow drilling contractors, operators and software vendors to build and deploy their own proprietary capabilities and leverage the solution’s foundation.

DrillOps Automate, a module in the on-target well delivery solution, can drill a stand by going on and coming off bottom, following parameters set by the user or specified in the digital drilling plan. Once on bottom, the solution optimizes the rate of penetration (ROP) within the limits specified for the section in the well plan. This solution monitors and automatically mitigates dysfunctions, such as shock and vibration or hard stringers.

It is important to realize that, just as self-driving cars are not merely the collection of driver assistance systems, such as adaptive cruise control and blind spot monitoring, this module is not simply a collection of reflexive responses but, like a self-driving car, is designed to adapt and respond appropriately to ever changing conditions with minimal user intervention.

Continuous improvement and sustainable performance

Schlumberger has deployed the automation solution in various rig environments, both on land and offshore, and each deployment has brought new lessons. Early proof-of-concepts were deployed on rigs in North America, the Middle East and Mexico, and connected real-time analysis desktop software applications to the rig’s control system.

These proof-of-concepts automatically adjusted control system parameters to optimize ROP and demonstrated the value of automation. However, it became clear that a scalable solution would require an industrialized automation platform designed for system stability, streamlined deployment and safety for real-time process control.

It also became apparent that an automation solution cannot execute as a disconnected system on a remote rig but must be coupled with cloud capabilities for remote workflow participation, analysis and support.

Safety is a key consideration for drilling and, therefore, a requirement for a drilling automation solution. The solution limits drilling operations to a prescribed safe operating envelope and takes advantage of the safety features and machine control of the rig control system. Additionally, in this digital era, cybersecurity is an essential safety element that cannot be bolted on to a system.

Well construction operations have procedures associated with them. Unfortunately, these procedures are not always followed. An early focus for deployments in the Middle East and North America was to drive procedural adherence. Graphs of real-time data show that automation can adhere to procedures in the way that no human ever could.

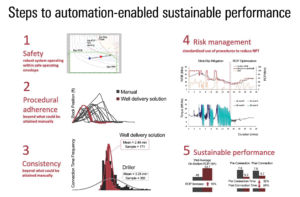

The block speed graph in Figure 2 shows profiles for a series of connections in automation and manual modes and illustrates the difference in procedural adherence achievable through automation. With procedural adherence comes consistency, without which it is impossible to learn or improve as there is too much variability. The frequency graph in Figure 2, from a rig in the Middle East, highlights the consistency that the automation system can achieve.

Once consistency has been achieved and the right procedures have been chosen, they can be deployed to other rigs or projects to enforce standardization. Analysis of the post-connection procedures on two rigs in the Middle East, prior to deployment, showed that there were four methods used for post-connections – one for each driller per shift per rig. After rolling out automation, the same procedures were applied with similar results across all rigs. The graphs in Figure 2 show the impact on post-connection operations. Replicating these results using the traditional training and dashboard monitoring approach is extremely difficult, especially when factoring in the rotation of individuals on the drilling crews.

Standardized procedures have delivered an important benefit in reducing nonproductive time. By enforcing and standardizing the same procedure throughout a fleet of rigs, all rigs had the same approach to detect and manage hard stringers, drilling dysfunctions, overpulls and other types of drilling challenges. As can be seen in Figure 2, the system can recognize the stick/slip erratic torque signature and automatically apply the mitigation procedure; once the stick/slip condition is mitigated, the system can resume ROP optimization. After rolling out the DrillOps solution, tool failure nonproductive time was reduced by 90%.

With each iteration through the plan, drill, record and learn well construction cycle, the optimal performance level comes closer within reach because it is built on a strong foundation supporting the overall process. The graphs in Figure 2 show the results obtained on the two rigs for connection times and ROP vs the field average.

Conclusion

Digital and automation technologies present the best opportunity for the drilling industry to innovate its way out of the current crisis. However, seizing the opportunity will require preparation, collaboration, participation and commitment to transform the way wells are drilled, to move away from working in isolation to working together to capitalize on each other’s strengths. Doing so will not only help the industry to survive this downturn but to thrive in the future.

When it comes to automation, all players have a key role to play, including operators, service companies and equipment manufacturers; however, rig contractors, as the owners and operators of the rig, are at the center of it all. Traditional methods, processes and business models must be challenged to find a way to create and sustain more value. DC

DrillOps is a mark of Schlumberger.