Plug locator system mitigates cement plug displacement risks

By Rebecca Caldwell and Bill Putman, Weatherford

The ongoing search for new oil and gas reserves continues to push the technical limits of well construction, as more complex wells are being drilled into increasingly remote reservoirs with higher-angle wellbores, higher pressures and temperatures and in deeper waters farther from shore. With this increased complexity comes greater risks in the form of safety, cost overruns and environmental exposure.

In light of these risks, the need for a high-quality primary cement job has become more critical. While much work has been done to improve primary cementing efficiency, it is widely recognized that the seemingly simple task of accurately locating the cementing plugs during cement displacement is a major factor in successful primary cementing. A successful bumping of the plugs provides a positive indication that the cement has been optimally placed, thereby allowing the casing to be tested and pressure-activated hangers or tools to operate, and minimizing drill-out time.

Volume discrepancies

While the industry realizes the importance of proper bumping of the top cementing plug, the cement volume required to bump the plug is often approximated based on the calculated casing volume. This volume may vary significantly from the actual string volume, particularly in the long and large-diameter subsea casing intervals that are becoming more common.

For example, the normal practice of calculating displacement volume is based on the casing’s internal diameter (ID), with some allowance for variations in wall thickness within API 5CT specifications.

A problem arises in determining how much that allowance should be. Standard procedures call for calipering the casing ID on selected joints and calculating the displacement volume based on their average. This procedure is not very accurate, and often the net result is that the planned volume is reached with an over-displacement allowance set at half of the shoe track volume. At that time, pumping is stopped regardless of the plugs’ location, which can lead to a substandard cement job.

Operators using dual cementing plugs have attempted to avoid displacement errors by calculating the cement volume required to bump the bottom plug. This method has historically proved unreliable due to the freefall effect of cement in the casing string and the fact that, in many cases, rupture of the bottom plug cannot be observed or recorded.

Improper placement of the cement plug in the string may create challenges during primary cementing operations. For example, if the top plug is set higher in the string than it should be, cement displacement ends prematurely, preventing the top plug from bumping. This effect tends to extend drill-out time, as the non-bumped plug may rotate with the bit rather than being efficiently drilled out, and it leaves excess cement above the float collar, which further increases drill-out time.

On the opposite side of the spectrum, a top plug that is lower in the string than anticipated results in the plug bumping unexpectedly at a high displacement rate. This may lead to plug bypass and subsequent over-displacement of the cement. In a worst-case scenario, this could lead to a wet shoe with a contaminated cement/mud mixture in place between the formation and the casing.

New indication approach

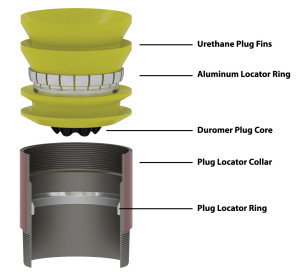

Weatherford developed a plug locator system that provides a positive indication on the rig floor of the top plug’s exact position in the casing string shortly before the plug bumps. The system incorporates a specialized locator collar installed in the casing string, several joints above the float or landing collar where the top plug is designed to land.

The top cementing plug is equipped with aluminum yield segments that impinge on the locator collar. An additional 300 to 700 psi (21 to 48 bar) is required to compress the yield segments into the plug’s outer body and allow the plug to pass through the collar. This produces a displacement pressure spike at surface, which indicates the precise location of the plug in the string. With this information, the operator can accurately displace the cement by pumping the precisely calculated volume between the locator collar and the float collar and land the plug.

This system minimizes the uncertainties in the pumped volume when using high-volume rig pumps to displace the cement. These pumps are prone to volumetric inefficiency, which when coupled with variations in liner size, sealing efficiency and stroke, can lead to a lower pumped volume than indicated by stroke counters. It also reduces fluid compressibility issues that may contribute to erroneous fluid volume measurements, particularly if the displacement fluid is aerated. This situation can lead to a considerable reduction of volume and a consequent error in the measurement of the amount of fluid being pumped into the well once it is placed under pressure.

By enabling controlled bumping of the plug, the system ultimately mitigates the risk of cement over or under displacement, thus ensuring optimal cement placement and preventing a wet shoe or excessive cement drill-out. Further, because both the locator collar and plug are fully PDC drillable, drill-out time is minimized.

Deepwater deployment

The new locator system was deployed while drilling a deepwater well in the Gulf of Mexico in 6,606 ft (2,014 meters) of water. The operator ran an intermediate 14 X 13 5/8-in. casing string in a 17-in. hole to a total measured depth (MD) of 24,892 ft (7,587 meters).

The string, which was run on drill pipe, consisted of:

• A 6 5/8-in., 39-lb/ft API full-hole drill pipe landing string;

• A 9 ¼-in. outside diameter (OD) multiple-opening diverter tool to divert fluid from the casing ID to the drill pipe annulus above the casing string and alleviate excess surge pressures;

• A 14-ft X 13 5/8-in. casing hanger equipped with subsurface release, non-rotating cementing plugs, with the top plug dressed with aluminum yield segments;

• Two joints of 14-in., 114-lb/ft casing;

• 13 5/8-in., 88.2-lb/ft casing to a plug locator collar set at 24,220-ft (7,382-meter) MD;

• 500 ft of 13 5/8-in., 88.2-lb/ft casing;

• A 13 5/8-in. autofill float collar with non-rotating profile set at 24,72-ft (7,535-meter) MD (Figure 1);

• A shoe track consisting of five joints of 13 5/8-in., 88.2-lb/ft casing; and

• A 13 5/8-in. guide shoe set at 24,892-ft (7,587-meter) MD.

Prior to the cement job, 20 casing joints were randomly selected and calipered to provide a composite average ID estimate of 12.4493-in. Based on this estimate, the operator calculated the total volume required to displace cement in all sections of the string. The volume of the drill pipe was 120 bbl, the casing to the locator collar was 2,637 bbl, and between the locator collar and float collar was 75 bbl, for a total displacement volume of 2,831 bbl.

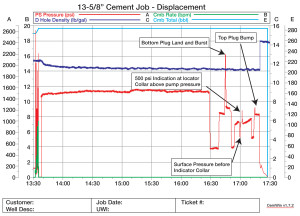

The cement job then commenced by pressure-testing the surface lines to 5,000 psi (345 bar), followed by pumping a 150-bbl spacer of 13.7-ppg mud into the well at 10 bbl/min and 820 psi (57 bar). The bottom plug dart was then dropped, and pumping of 16.4-ppg cement commenced. After pumping 125 bbl of cement, the dart latched into the bottom plug, and it sheared out at 1,750 psi (121 bar).

After additional pumping until a total volume of 233 bbl of cement had been displaced, the top plug dart was dropped, and a further 6 bbl of cement was pumped. The rig pumps were then used to continue displacement, with volumes measured by a stroke counter. The pumping fluid was switched to 13.2-ppg mud, and after 120 bbl had been pumped, the top dart landed and the top plug sheared out at 2,700 psi (186 bar).

Pumping continued at a rate of 10 bbl/min until the bottom plug landed and sheared out after 27,400 strokes of the pump, which was 950 strokes, or 93 bbl, later than initially calculated. The pump rate was slowed to 5 bbl/min, and when the top plug passed the locator collar, a pressure spike of 500 psi (34 bar) was observed at surface. A further 77 bbl was pumped at 5 bbl/min until the top plug landed and the pressure increased to 1,150 psi (79 bar), indicating a completion of the cement displacement. The total number of strokes was 29,740, which corresponded to a total of 2,918 bbl of displacement vs the 2,831 bbl that was calculated. The entire cement job, which is represented graphically in Figure 2, was carried out without surface returns.

Without the plug locator system present, cement displacement would have stopped some 93 bbl before the top plug landed, which would have resulted in an additional 620 ft (189 meters) of cement having to be drilled out to reach the float collar. This job illustrated the problems associated with large-volume subsea cementing jobs. Plug landing occurred at a displacement volume that was 93 bbl more than calculated due to the combination of ID deviations, pump inefficiency and fluid-compressibility inaccuracies.

The new locator system addressed these volume measurement discrepancies with a high degree of accuracy. The critical volume measurement of 77 bbl between the locator collar and float collar matched closely with the calculated estimate of 75 bbl.

This field trial demonstrated the contribution that a plug locator system can make to improve the quality and economics of primary cement jobs by increasing the reliability of top plug bumping. The company continues to make design upgrades to the system, such as the installation of a collet around the plug, which allows more than one collar locator to be placed in the casing string and provides the ability to verify plug location at different points in the casing.

This technology has proven valuable to both the quality and economics of cement jobs, not only in the Gulf of Mexico but also in other deepwater regions where risk mitigation and cementing efficiency are equally as important.