Bit of best fit

Vector-accurate PDC bits target unconventionals as hybrid bits address complex wells, interbedded formations

By Katie Mazerov, contributing editor

When TOTAL E&P UK drilled an exploratory well last year in the remote Tomintoul field, located west of the Shetland Islands, the event marked a milestone in the company’s quest to access the potential reservoir in the frigid waters of the Atlantic Ocean. In addition to the location and harsh weather conditions posing significant technical challenges, the field features a layer of very hard, volcanic rock above the reservoir.

To drill through the difficult volcanic formation, TOTAL used a tool initially developed using experience acquired from numerous bi-center bit runs, featuring a concentric, two-stage, dual-diameter PDC bit design. Run on a low-speed/high torque motor bottomhole assembly (BHA), the system provided sufficient energy, stability and durability to deliver a single BHA/single bit drilling solution for the entire section, including the challenging volcanic layer.

“Volcanic rock is very hard and abrasive and can result in considerable vibration on the BHA and the drill string,” explained Nicolas Baudouin, senior drilling engineer for TOTAL E&P UK. The bit, National Oilwell Varco’s (NOV) SpeedDrill bit, drilled the entire 12.25-in. section, a distance of more than 3,280 ft (1,000 meters) with one BHA/bit at an average rate of penetration (ROP) of 36 ft/hr (11.3 meters/hr); ROP through the 98-ft (30-meter) thick olivine basalt ranged between 3-32 ft/hr (1-10 meter/hr), Mr Baudouin said.

“The bit initially drills a smaller, 9.875-in. pilot section, which has the effect of stress-relieving the surrounding rock, while the reamer section subsequently enlarges the hole to the required diameter through this previously stress-relieved rock, requiring less energy and resulting in more efficient drilling,” he continued.

The operation was the first time a SpeedDrill bit had been used in the UK and proved its efficiency in a range of rock types, including abrasive volcanic rock.

With today’s technologies, hard-rock formations, long laterals in unconventional shale plays, harsh, extended-reach deepwater wells and interbedded reservoirs are no longer out of reach for operators. However, drilling objectives remain: optimized ROP, efficiency and reduced drilling costs. At the top of operators’ wish lists are bit designs that decrease torque and vibration and can drill a well in one run. Upfront formation evaluation to better determine drilling conditions also is playing an increasing role in helping companies select the correct bit design and technology.

Polycrystalline diamond compact (PDC) bits, which have become dominant in the industry over the past 10 years, as well as roller cone bits, have evolved to meet new drilling challenges. Harsh formations – typically abrasive, interbedded and hard with varying layers of soft rock (such as shale), hard rock (such as dolomite) and abrasive rock (such as sandstone) – may require one or a combination of enhanced steerabilty, stability and durability and aggressiveness in the bit. Very hard rock may be abrasive and is typically not interbedded. Here, drill bit stability and durability are most important.

Different challenges

“In today’s drilling environment, there are different sets of challenges depending on where we are in the field,” NOV’s Ryan Weeden, product line manager, Drill Bits, said. “In deepwater wells, for example, the upper well section is typically very soft, with a lot of swelling that can decrease the wellbore diameter. The lower sections can be mildly harsh with some interbedding.”

Related Article:

PDC bit with conical element targets rock cutting at bore center

In a typical GOM operation, where a large-diameter hole is drilled at the top of the well, steerabilty and stability are most important because the wide ratio between a 26-in. bit and a 6.5-in. outer diameter (OD) pipe leaves a lot of room for the pipe to move around and cause vibration.

“When we get farther downhole, that ratio of bit diameter versus drill pipe becomes much smaller, but the environment is much harsher, with vibration resulting from interaction of the bit with the formation. Stability, durability and aggressiveness then become important.”

Bit designs that can accommodate these varying conditions and still deliver high ROP are driving innovation. “For a deepwater GOM well, SpeedDrill provides the stability and steerability for the large-diameter hole in the softer upper section but can adapt to the harsher environment downhole with durability, stability and aggressiveness,” Mr Weeden said. The bit also has the ability to transition from soft to hard rock without skating from side to side, a phenomenon that can cause lateral stability problems, contributing to poor wellbore quality and equipment damage.

By featuring both a bit and reamer, the bit also can be oriented to provide continuous contact with the wellbore through the sides of the bit, or gauge pads. “A conventional single-diameter PDC bit will provide 50% gauge pad contact with the wellbore, while SpeedDrill offers 100% contact,” he said. “That provides a lot of lateral stability.” The design also allows the bit to effectively create a pilot hole while reaming so the hole can be drilled faster, straighter, smoother and with less stress, he said.

Cutter technology also has advanced in recent years, providing greater thermal stability and breakage resistance. NOV’s Helios cutter are designed to resist thermal fatigue while drilling, especially in abrasive formations where the cutters generate a lot of heat, expand, overheat and cause breakage, Mr Weeden said.

The company’s Titan Ultra bit, which delivers stability and steerabilty, has been used to drill ultra-large diameter holes in Australia, Brazil, Russia and the GOM, where it has set speed and length records. For directional drilling, the Seeker directional bit was used to drill the longest extended-reach well ever drilled, 7.62 miles, from Sakhalin Island. The Seeker S bit provides a special hydraulics component to facilitate faster drilling while performing hole-cleaning.

Over the past decade, the industry has seen a trend toward hybrid bits, such as the FuseTek bit, which combines PDC bits with impregnated material for challenging formations. “We start out with the PDC bit, and when the cutter wears out, we can transition to the impregnated bits, reducing trip time,” Mr Weeden said.

Best of both worlds

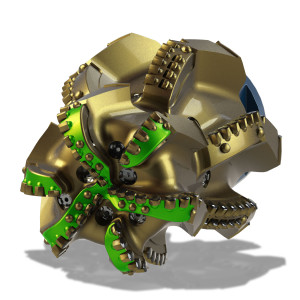

The Hughes Christensen Kymera hybrid bit technology from Baker Hughes combines PDC fixed cutters and roller cones into a single design that addresses drilling challenges in complex wells and interbedded formations. “This technology combines the best of both worlds,” said Bob Welch, product line manager, tricone, hybrid, casing and liner bits. “The smooth, low-torque crushing action of roller cones is combined with the aggressive shearing of the PDC blades to improve drilling efficiency and reduce costs. The Kymera bits can successfully drill through challenging lithologies of interbedded formations and provide smoother toolface control in directional wells, delivering greater overall ROP potential than conventional bits.”

The bit has applications in deepwater wells because it limits torque oscillations in larger-diameter holes where PDC bits can trigger stick-slip. “Kymera hybrid bits provide an efficient cutting mechanism for the amount of available power,” Mr Welch explained. “In large-diameter holes, torque becomes a limiting factor with PDC drill bits. Hybrid technology provides better vibration control, which leads to increased drilling efficiency and better reliability, resulting in reduced costs. By reducing vibration in the other components in the BHA, the bit also helps extend the life of the tools.”

In Latin America, a Kymera bit drilled 2,241 ft (683 meters) of interbedded shale, sandstone and limestone formation in one run in the 17.5-in. section of an exploratory well. The operation exceeded planned ROP by 17%, minimized shock and vibration and protected the cutters from impact damage.

The bit also achieved an ROP of 18 ft/hr (5.5 meters/hr) in a vertical application while drilling a geothermal well in Central Europe. The well was located in an interbedded formation of sandstone, mudstone, clay, siltstone and conglomerate. The bit drilled 2,966 ft (904 meters), the longest run recorded in the same formation, reducing nonproductive time and costs.

Kymera bits are being used in 21 countries and have had more than 1,000 runs, said Alan Holliday, Kymera bit product manager for Baker Hughes. “Globally, we see a lot of applications where we’re able to replace multiple bits on offsets, sometimes at anywhere from two to four times the ROP.”

Baker Hughes recently launched its Hughes Christensen Talon high-efficiency PDC bits, initially in the US unconventional market and then expanded into conventional and non-US markets. “Our objective is to help customers reduce overall drilling costs and consistently perform in all applications by focusing on the mechanical, hydraulic and cutting efficiencies of the bit,” said Matt Meiners, product line manager, diamonds, for Baker Hughes.

The Talon 3D vector-accurate PDC bit was designed for unconventional plays. “Shale plays require more hydraulic efficiency, directional control and reliability to extend the run life and ultimately reduce the number of days on well,” he explained.

In 2012, a Talon bit drilled the curve section of a well in the Eagle Ford Shale, improving single-run ROP by approximately 93%. The bit drilled a 932-ft (284-meters) curve section in 14 hours, averaging nearly 67 ft/hr (20 meters/hr), the fastest curve performance for the operator in this field. The bit drilled a total 1,495 ft (456 meters) with build rates from 10° to 13° per 100 ft and emerged from the hole with no damage to the cutting structures. For this application, Baker Hughes used the DART process, which incorporates knowledge of formation characteristics to optimize the bit solution.

In the Middle East, Talon bits has set multiple drilling records in a four-well campaign, including the longest, deepest and fastest runs. In the first run, the 12.25-in. bit drilled 5,387 ft (1,642 meters) vertically at an average ROP of 99.9 ft/hr (30.5 meters/hr), 28% faster than the previous record. Based on this success, the same operator chose Talon bits in additional gas development wells, setting additional records for shoe-to-shoe runs for comparable intervals.

Single-bit wells

In the North American unconventional market, operators indicate a growing desire to drill all well sections – vertical, curve and lateral – with just one bit as well as high ROP. “Operators are trying to do things with bits that we haven’t necessarily considered, which is forcing us to come up with the new and better designs and technology,” said Cary Maurstad West Hemisphere product manager for Varel Industries.

Drilling with one bit can reduce trips to change out the BHA for the three sections of an unconventional well, but there is the risk of compromising cutter and bit design because each section is different. “Formation, BHA vibration and directional drillers all influence how a bit works,” Mr Maurstad said. “Ultimately, we have to build a product that can run in many situations and is more universal in its usage.”

Varel’s new Voyager PDC bit, designed to deliver smooth torque, directional control and stability in directional wells, is compatible with multiple directional drive systems.

Operators are driving the one-bit trend in the prolific Bakken and Eagle Ford plays, while in West Texas they are still perfecting the art of drilling the lateral sections in hard, abrasive formations that require multiple bits, he added. “West Texas is characterized by layered formations that go back and forth between sand, carbonate and lime,” he explained. “Then, once we get into the formation laterally, we see chert, a type of sedimentary rock that can be layered or nodular.” Nodular rock can destroy bits, resulting in multiple bit runs and changeouts.

The one-bit methodology also is surfacing in other regions, notably the Middle East and the deepwater presalts in West Africa. Varel is developing a hybrid solution for harsher, deeper environments, including high-pressure, high-temperature (HPHT) wells, that would combine impregnated technology with PDC bits, said Bruno Cuillier, Eastern Hemisphere product manager for Varel. “The main cutting structure would be a PDC, backed up with impregnated material to extend the bit life,” he said. “We’re also working on increasing the strength of the PDC assembly to avoid bit fatigue downhole.”

For HPHT applications, Varel also is using stronger API steel. But making the bit more robust is only part of the solution, Mr Cuillier believes. “We’re seeing a big push to do more upfront formation analysis to determine, for example, what kind of cutting structures are needed to drill these complex reservoirs.”

Understanding the formation

Halliburton uses its Design at the Customer Interface (DatCI) process to apply the appropriate bit technology and design based on customer goals and drilling conditions. “There are different conditions and applications throughout the world, all of which require different technology and thinking,” said Brad Dunbar, fixed cutter product manager for Halliburton. “The first challenge in the DatCI process is understanding the formation, including rock strength and abrasiveness, interbedding, degree of instability and plastic condition, that will be drilled to best determine which cutting structure to design.”

Halliburton’s application design evaluation specialists learn the various applications for their assigned areas, talk to local customers about their goals and evaluate drilling conditions to determine the equipment capabilities that will be needed to produce a record-setting bit, he explained.

“By collaborating with both customers and users of drill bits, we ensure that everyone understands the goals and expectations. With this process, we have been able to rapidly produce new designs for ever-improving length of runs, directional capabilities and ROP in a complete cycle time that is less than one month.”

Last year, Halliburton introduced MegaForce, a PDC bit that provides enhanced cutting structure and matrix material, multilevel force balancing, hydraulics and shank length for increasingly deeper and longer wellbores in unconventional plays. “The multilevel force balancing keeps groups of cutters balanced as transitions in formations are traversed, reducing vibration and damage,” Mr Dunbar said. Earlier this year, an 8 ¾-in. MegaForce bit was used to drill a 5,131-ft (1,564 meters) lateral section with water-based mud in the Eagle Ford. The recorded ROP was the fastest for the operator using water-based mud in the play.

The company also made improvements in PDC cutter technology to improve thermal mechanical integrity and reduce abrasion in difficult-to-drill applications. “At the same time, improvements in impact resistance have led to less breakage on the cutters, ensuring bits are drilling the intervals as fast as possible,” Mr Dunbar said.

Halliburton has also enhanced seals, barriers and grease to develop a new roller cone bit. In the Utica, a 12 ¼-in. QuadPack Plus bit drilled a 2,619 ft (796 meters) vertical interval in 26.5 hours at an ROP of 98.5 ft/hour. The bit outdrilled a competitor on the same pad in both footage and ROP, with a better dull grade.

“These improvements, combined with our Energy Balanced technology, result in equal amounts of energy downhole and rock removed being distributed evenly over all three cones on the bit,” said Guy Phaneuf, roller cone product manager. “The result is longer bit life and more consistent performance.”

SpeedDrill, Helios, Titan Ultra, Seeker, FuseTek and DuraDiamond Evolution are trademarked terms of NOV.

Kymera, Talon, Talon 3D and DART are trademarked term of Baker Hughes.

Voyager is a trademarked term of Varel Industries.

DatCI is a service mark of Halliburton; MegaForce is a trademarked term of Halliburton; Energy Balanced and QuadPack are registered terms of Halliburton.