2014 OTC Spotlight on New Technology Awards

The Offshore Technology Conference has announced the 12 winning technologies that will receive the 2014 Spotlight on New Technology Awards recognizing innovative technologies significantly impacting offshore exploration and production.

Winning technologies are selected based on five criteria:

• New: The technology must be less than two years old.

• Innovative: The technology must be original, groundbreaking and capable of revolutionizing the offshore E&P industry.

• Proven: The technology must be proven, either through full-scale application or successful prototype testing.

• Broad interest: The technology must have broad interest and appeal for the industry.

• Significant impact: The technology must provide significant benefits beyond existing technologies.

Geoservices, a Schlumberger company, has developed the FLAG fluid loss and gain detection service, which aims to meet the growing challenges of complex drilling programs in deepwaters with an early warning system that is highly sensitive to fluctuations but intelligent enough to help prevent false alarms. With faster response time compared with previous systems, the FLAG service provides accurate fluids monitoring and Coriolis flow metering in operating conditions, including drilling, tripping, circulating and cementing.

Geoservices, a Schlumberger company, has developed the FLAG fluid loss and gain detection service, which aims to meet the growing challenges of complex drilling programs in deepwaters with an early warning system that is highly sensitive to fluctuations but intelligent enough to help prevent false alarms. With faster response time compared with previous systems, the FLAG service provides accurate fluids monitoring and Coriolis flow metering in operating conditions, including drilling, tripping, circulating and cementing.

GE Oil & Gas’ SeaLytics solution enables drilling contractors to monitor performance and plan maintenance of BOPs using predictive analytics based on actual component performance data. SeaLytics can improve BOP system uptime, reduce unnecessary maintenance and lead to better cost forecasting, all of which provide significant performance benefits to the user.

GE Oil & Gas’ SeaLytics solution enables drilling contractors to monitor performance and plan maintenance of BOPs using predictive analytics based on actual component performance data. SeaLytics can improve BOP system uptime, reduce unnecessary maintenance and lead to better cost forecasting, all of which provide significant performance benefits to the user.

SBM Offshore’s high-pressure fluid swivel increases the operating range of high-pressure swivels by using a patented technique to cascade the pressure drop over multiple seals. The 12-in. prototype toroidal swivel has been qualified to 830 barg, including long-term endurance test runs, and has the potential to operate at over 1,000 barg. The swivel is aimed at gas or water injection from FPSOs into ultra-high-pressure reservoirs, such as the Lower Tertiary fields of the Gulf of Mexico.

SBM Offshore’s high-pressure fluid swivel increases the operating range of high-pressure swivels by using a patented technique to cascade the pressure drop over multiple seals. The 12-in. prototype toroidal swivel has been qualified to 830 barg, including long-term endurance test runs, and has the potential to operate at over 1,000 barg. The swivel is aimed at gas or water injection from FPSOs into ultra-high-pressure reservoirs, such as the Lower Tertiary fields of the Gulf of Mexico.

Halliburton’s TDReam tool provides the benefits of optimized steerability and fluid flow and reduced tool length based on the proven reliability of the Near Bit Reamer technology. The TDReam tool is designed to significantly reduce rathole length and reach TD in one run, increasing efficiency and saving rig time.

Halliburton’s TDReam tool provides the benefits of optimized steerability and fluid flow and reduced tool length based on the proven reliability of the Near Bit Reamer technology. The TDReam tool is designed to significantly reduce rathole length and reach TD in one run, increasing efficiency and saving rig time.

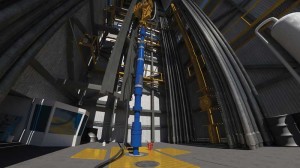

FMC Technologies Schilling Robotics’ ISOL-8 pump enables secondary intervention for BOPs in compliance with API 53. The pump is integrated with FMC’s UHD III remotely operated vehicle (ROV) and meets the 45-sec requirement for closing BOP shear rams. The pump consists of independent pistons synchronized with software control. Flexible configuration allows optimization for a variety of demands and can simultaneously provide up to 50 gpm at 5,000 psi. Compared with existing industry solutions, according to FMC, this system is depth insensitive and can save operators up to $4 million per rig.

FMC Technologies Schilling Robotics’ ISOL-8 pump enables secondary intervention for BOPs in compliance with API 53. The pump is integrated with FMC’s UHD III remotely operated vehicle (ROV) and meets the 45-sec requirement for closing BOP shear rams. The pump consists of independent pistons synchronized with software control. Flexible configuration allows optimization for a variety of demands and can simultaneously provide up to 50 gpm at 5,000 psi. Compared with existing industry solutions, according to FMC, this system is depth insensitive and can save operators up to $4 million per rig.

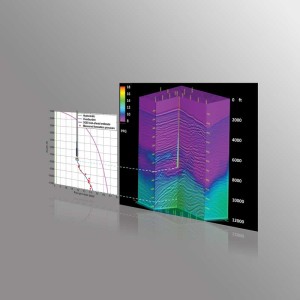

Schlumberger’s Seismic Guided Drilling (SGD) predicts formation pressures hundreds of meters ahead of the bit while drilling. The SGD service uses both surface seismic and logging-while-drilling (LWD) data to provide a 3D velocity model. This model leads to better geological and geomechanical description, enabling proactive drilling decisions, particularly in deepwater exploration. Velocities ahead of the bit are re-calculated from seismic reflections by using LWD velocities behind the bit as a constraint. Compared with pre-drill predictions, this provides more accurate results, which can be used in velocity-to-pressure transforms to give more reliable formation pressures.

Schlumberger’s Seismic Guided Drilling (SGD) predicts formation pressures hundreds of meters ahead of the bit while drilling. The SGD service uses both surface seismic and logging-while-drilling (LWD) data to provide a 3D velocity model. This model leads to better geological and geomechanical description, enabling proactive drilling decisions, particularly in deepwater exploration. Velocities ahead of the bit are re-calculated from seismic reflections by using LWD velocities behind the bit as a constraint. Compared with pre-drill predictions, this provides more accurate results, which can be used in velocity-to-pressure transforms to give more reliable formation pressures.

Weatherford’s CasingLink EM Antenna System was developed to address the signal attenuation encountered while drilling in deeper depths with an electromagnetic (EM) telemetry system. This method employs an insulated wire that is externally attached to a standard casing string, a borehole receiver typically located downhole and connected to the casing, and a surface transceiver. The borehole receiver picks up the EM signal at the casing connection terminal and transmits it via the external signal wire to the surface transceiver, which decodes the EM signal. The wire exits the casing near the surface and passes through a wellhead modified to accept the cable pass-through. There is negligible signal attenuation within the transmission wire, which increases telemetry depth.

Weatherford’s CasingLink EM Antenna System was developed to address the signal attenuation encountered while drilling in deeper depths with an electromagnetic (EM) telemetry system. This method employs an insulated wire that is externally attached to a standard casing string, a borehole receiver typically located downhole and connected to the casing, and a surface transceiver. The borehole receiver picks up the EM signal at the casing connection terminal and transmits it via the external signal wire to the surface transceiver, which decodes the EM signal. The wire exits the casing near the surface and passes through a wellhead modified to accept the cable pass-through. There is negligible signal attenuation within the transmission wire, which increases telemetry depth.

West Production Technology AS has developed the SwarfPak for plug and abandonment and slot recovery with reduced rig time and reduced environmental footprint. With SwarfPak, all the swarf particles will be deposited and left downhole, avoiding the use of surface swarf handling equipment, which can pose logistical and environmental challenges. The technology also can increase the milling speed to three to six times faster than conventional milling technology.

West Production Technology AS has developed the SwarfPak for plug and abandonment and slot recovery with reduced rig time and reduced environmental footprint. With SwarfPak, all the swarf particles will be deposited and left downhole, avoiding the use of surface swarf handling equipment, which can pose logistical and environmental challenges. The technology also can increase the milling speed to three to six times faster than conventional milling technology.

Baker Hughes’ LaunchPRO wireless top drive cement head is a remote-activation system for deepwater applications. The technology launches balls, plugs or darts wirelessly during cementing of extremely heavy and long subsea strings and long, heavy liners. LaunchPRO’s remote wireless operation reduces HSE risks by reducing manual intervention and rig time, while optimizing reliability. Its operation is powered by rig air through a single pneumatic hose that can be tethered to the cementing line to reduce the risk of damage during cementing operations. A wireless pressure transducer provides real-time data to the cementing operator to allow for adjustments during cementing operations.

Baker Hughes’ LaunchPRO wireless top drive cement head is a remote-activation system for deepwater applications. The technology launches balls, plugs or darts wirelessly during cementing of extremely heavy and long subsea strings and long, heavy liners. LaunchPRO’s remote wireless operation reduces HSE risks by reducing manual intervention and rig time, while optimizing reliability. Its operation is powered by rig air through a single pneumatic hose that can be tethered to the cementing line to reduce the risk of damage during cementing operations. A wireless pressure transducer provides real-time data to the cementing operator to allow for adjustments during cementing operations.

FMC Technologies’ Offshore Footless Loading Arm (OLAF) has been developed for LNG transfer between floating LNG (FLNG) and conventional LNG carrier, in side-by-side moored arrangement in offshore conditions. The OLAF design is able to accommodate the large elevation differences between the FLNG deck, where it is based, and the LNG carrier piping connection at lower level, without overloads. OLAF covers 100% of side-by-side operability in harsh environmental conditions with its targeting system for connection assistance and Constant Position Monitoring System to manage the emergency disconnection.

FMC Technologies’ Offshore Footless Loading Arm (OLAF) has been developed for LNG transfer between floating LNG (FLNG) and conventional LNG carrier, in side-by-side moored arrangement in offshore conditions. The OLAF design is able to accommodate the large elevation differences between the FLNG deck, where it is based, and the LNG carrier piping connection at lower level, without overloads. OLAF covers 100% of side-by-side operability in harsh environmental conditions with its targeting system for connection assistance and Constant Position Monitoring System to manage the emergency disconnection.

WesternGeco’s IsoMetrix marine isometric seismic technology enables 3D measurement of seismic wave fields using towed streamers. It delivers high-fidelity point-receiver seismic data while overcoming spatial bandwidth compromises that limited previous towed-streamer methods. The technology has a streamer design that includes measurement of the vertical and crossline gradient of the seismic wave field that enables unaliased reconstruction of the pressure wavefield between the streamers. The resulting isometric sampling in crossline and inline directions provides accurate images of the subsurface, making the data suitable for many reservoir modeling applications in exploration and reservoir development.

WesternGeco’s IsoMetrix marine isometric seismic technology enables 3D measurement of seismic wave fields using towed streamers. It delivers high-fidelity point-receiver seismic data while overcoming spatial bandwidth compromises that limited previous towed-streamer methods. The technology has a streamer design that includes measurement of the vertical and crossline gradient of the seismic wave field that enables unaliased reconstruction of the pressure wavefield between the streamers. The resulting isometric sampling in crossline and inline directions provides accurate images of the subsurface, making the data suitable for many reservoir modeling applications in exploration and reservoir development.

GE Oil & Gas’ Zenith GFI Ground Fault Immune ESP monitoring system offers a solution that cannot be disturbed by ground faults. The system empowers operators with the ability to maintain well surveillance essential for production optimization and pump protection, despite fault conditions.

GE Oil & Gas’ Zenith GFI Ground Fault Immune ESP monitoring system offers a solution that cannot be disturbed by ground faults. The system empowers operators with the ability to maintain well surveillance essential for production optimization and pump protection, despite fault conditions.