People, Companies and Products

Chevron announces agreement to acquire Noble Energy

Chevron has entered into a definitive agreement with Noble Energy to acquire all of the outstanding shares of Noble Energy in an all-stock transaction valued at $5 billion. The total enterprise value of the transaction, including debt, is $13 billion.

The acquisition provides Chevron with low-cost, proved reserves and attractive undeveloped resources that will enhance its upstream portfolio. Noble Energy brings low-capital, cash-generating offshore assets in Israel, strengthening Chevron’s position in the Eastern Mediterranean. Noble Energy also enhances Chevron’s US unconventional position with de-risked acreage in the DJ Basin and 92,000 largely contiguous and adjacent acres in the Permian Basin.

Based on Noble Energy’s proved reserves at year-end 2019, this will add approximately 18% to Chevron’s year-end 2019 proved oil and gas reserves at an average acquisition cost of less than $5/BOE, and almost 7 billion bbl of risked resource for less than $1.50/BOE.

Investment firm acquires equipment repair company MRDS

Drilling equipment repair company MRDS has been acquired by Aberdeen-based investment firm Garrick Group for an undisclosed amount. MRDS, which specializes in project management, inspection, repair and overhaul of oilfield drilling equipment, will continue to operate from its premises in Altens, Aberdeen.

The acquisition will help sustain the company’s position globally and enable the company to grow into new markets. Ronnie Garrick will take on the role of Executive Chairman at MRDS, while Ian McGillivray, previously Sales Director, will become Managing Director. Company founder Mark Robertson has been retained in a technical consultancy role.

Wild Well Control, OSRL form strategic alliance

Wild Well Control and Oil Spill Response Limited (OSRL) have signed a strategic alliance agreement to enhance the capabilities of the Global Subsea Response Network’s services, as provided through OSRL’s Subsea Well Intervention Services.

Patrick Schorn joins Borr Drilling as new CEO

Borr Drilling has appointed Patrick Schorn as its new CEO, effective 8 September 2020. Mr Schorn will succeed Svend Anton Maier, who will remain with the company as Special Advisor to the CEO.

Mr Schorn has been a director of the company since January 2018. He was previously Executive VP of Wells for Schlumberger. Prior to that, he held various positions with Schlumberger, including President of Operations; President Production Group; President of Well Services; President of Completions; and GeoMarket Manager Russia.

Mr Schorn holds a Bachelor of Science in oil and gas technology from the University “Noorder Haaks” in Den Helder, the Netherlands.

Halliburton deal aims to enhance digital capabilities

Halliburton, Microsoft and Accenture have begun a five-year strategic agreement to advance Halliburton’s digital capabilities in Microsoft Azure. Under the agreement, Halliburton will complete its move to cloud-based digital platforms and strengthen its offerings by:

- Enhancing real-time platforms for expanded remote operations;

- Improving analytics capability, with the Halliburton Data Lake utilizing machine learning and artificial intelligence; and

- Accelerating the deployment of new technology and applications.

Weatherford inks deal with Iraqi Drilling Company

Weatherford has signed an 18-month contract with Iraqi Drilling Company (IDC) to provide services and project management for the drilling and completion of 20 wells in the Al-Nasiriyah field in the Dhi Qar province in southern Iraq.

IDC will provide rigs, civil works and drilling services; Weatherford will provide project management and all other associated services. The operation will be performed with four rigs provided by IDC.

OneSource partners with Daubert Cromwell

OneSource, a Norway-based provider of drilling rig preservation solutions for stacking and lay-ups, has partnered with Daubert Cromwell, a manufacturer of volatile corrosion inhibitor (VCI) protection for metals, have entered into a strategic alliance. The goal is to combine both companies’ expertise in greenfield and brownfield projects, stacking, preservation and engineering with VCI solutions.

Exceed MPR introduces new rig integration service

Exceed MPR has launched a specialist rig integration service, which completes the spectrum of MPD services it provides and allows the company to provide clients with a turnkey service. Further, the company has appointed Jon Goodenough as Rig Integration Manager.

Turan to manage BP procurement activity

Turan Drilling & Engineering Company, a KCA Deutag and SOCAR AQS company, has been awarded a contract amendment to manage procurement, maintenance and warehousing activities on behalf of BP Exploration (Caspian Sea). Turan will manage the SAP maintenance system, wells procurement activity, inventory, storage and warehousing for the BP global wells organization in Azerbaijan. An additional 71 people have been hired to support this activity, 69 of whom are Azerbaijani nationals.

PRODUCTS

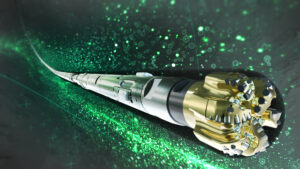

New rotary steerable service leverages near-bit sensors

Baker Hughes has introduced the Lucida advanced rotary steerable service, which integrates hardware, software, automation and remote connectivity. The service is designed to maximize directional drilling performance and well productivity by incorporating advanced electronics and near-bit sensors that enable drillers to more precisely guide bottomhole assemblies.

Its integrated bottomhole assembly (BHA) includes a customized drill bit and proprietary high-strength connections to maximize penetration rates. The BHA also includes near-bit sensors to gather more downhole data and multi-chip module electronics, which have been tested extensively at temperature cycles approaching 400°F to provide a step change in reliability in more demanding drilling environments.

The service’s 16-sector gamma-ray sensors are situated close to the bit and provide real-time formation data that enable quick decisions to navigate the reservoir.

Its automated well path trajectory control system integrates both azimuthal and inclination hold modes with continuous proportional steering to automatically correct the wellbore trajectory for formation trends.

New system uses automation to prevent swinging loads

Columbus McKinnon has launched the Magnetek brand Intelli-Lift System, which leverages automation to help prevent load swing caused by load misalignment when the rope and hook are not vertical. It also detects snagged conditions that can occur along the travel path, or when moving hooks, slings and rigging to the next lift, and stops all motions.

The system alerts operators with a visible and audible warning before a dangerous load misalignment or snag condition occurs. Using sensors and a status control enclosure, the system activates directional lights and a programmable warning horn if it detects a side pull or off-center pick. It will then assist operators to center the bridge and trolley over the load before it is hoisted.

Digitally connected service delivers real-time insights

Schlumberger has introduced the Performance Live digitally connected service. It includes technology and domain expertise within a digital ecosystem, leveraging cloud-based applications and automated data workflows through a secure data network.

The service provides access to data and collaboration with domain experts, enabling faster, more informed decision making for directional drilling, well logging, formation testing and other operations. The service is used by more than 60% of Schlumberger well drilling jobs worldwide.

International SOS offers screening service

UK-based International SOS has rolled out a screening service that can help get people back to work. During the lockdown, the company helped to ensure essential offshore workers were safe to work by conducting temperature and vulnerability screenings. The experience led to the development of robust procedures and services that include risk assessments, infection control procedures and testing, and the provision of an entry screening service. In addition, the company is offering a COVID-19 polymerase chain reaction testing service, which can be offered at the company’s clinics, at customer premises, or at the employee’s home.

Ballast system completes IMO G8 test program

Optimarin has completed testing of the Optimarin Ballast System (OBS) in accordance with the revised IMO G8 guidelines, while also upgrading its existing US Coast Guard (USCG) approval certificates to ensure compliance for zero to two hours holding time. The testing procedures were conducted at the NIVA test facility in Norway from September 2019 to the end of June 2020, with DNV GL operating as the designated independent laboratory.

Tube integrity technology offers improved accuracy

TGT recently launched Pulse1, a slim-hole tube integrity technology that delivers actual wall thickness measurements in eight sectors with all-around sensing of tube wall condition. This diagnostic capability enables operators to assess the condition of production tubulars more accurately than previously possible, ensuring safe, clean and productive well operations.