With BSEE Well Control Rule in force, it’s time to take another look at RFC-HSE variant of MPD

Technique allows for increase in equivalent mud weight with modest application of surface back pressure at first indication of well flow

By Don Hannegan, Managed Pressure Drilling; Bhavin Patel, Harshad Patil and Maurizio Arnone, Weatherford; Jerry Lee, University of Houston

Drilling techniques associated with closed and pressurizable circulating mud systems have become standard on land drilling programs over the past several decades. This progression can be measured by the growth in rental activity of rotating control devices (RCDs). Because these techniques and technologies have proven effective onshore, greater application in marine environments seems uniquely logical.

A closed-loop system – comprising drillstring non-return valves, a fit-for-purpose RCD and a drilling choke – enables drillers to positively direct mud returns away from the rig floor and suppress influxes by quickly increasing equivalent mud weight. This offers the driller several advantages: keeping kick volumes small, minimizing downtime spent on well control scenarios, enabling drilling further from the fracture gradient and nearer to the formation gradient, and reducing lost-circulation incidents that may compromise the primary well control barrier (hydrostatic pressure).

Drilling with a closed-loop system has become standard operating procedure on US and Canadian land drilling programs, where it is often required by insurance underwriters and federal or municipal governments.

When these land-proven methods of mitigating drilling hazards were introduced to the offshore industry in 2004, they were categorized in context of the types of drilling challenges each had been proven to address and described as “variants” of managed pressure drilling (MPD). These are:

• Constant bottomhole pressure (CBHP) for drilling in narrow margins;

• Pressurized mud-cap drilling (PMCD) for dealing with severe to total loss zones;

• Dual-gradient drilling (DGD) for drilling in relatively depleted formations in deepwater; and

• Returns flow control for health, safety, and environmental considerations (RFC-HSE).

The RFC-HSE variant is the focus of this article. The Well Planning chapter of IADC Deepwater Well Control Guidelines, under the MPD Option section, describes RFC-HSE MPD as “a variation of MPD applicable to drilling with conventional fluids and well construction programs.” The equipment set-up would be similar, if not identical, to CBHP MPD. However, the purpose is simply to enhance the utility of the primary well control barrier by drilling with a closed-loop system.

Using a closed-loop system, the RFC-HSE variant of MPD facilitates early kick-loss detection, identifying wellbore ballooning/breathing, and using surface backpressure (SBP) to suppress an influx of reservoir fluids. The system could also be used to conduct dynamic formation integrity tests (FITs) and leak-off tests (LOTs) to ascertain downhole conditions.

Background

As envisioned, an RFC-HSE MPD system comprised an RCD installed on top of a land rig’s BOP to positively divert annular returns from beneath the rig floor. However, in marine environments, this variant evolved to include technologies that not only detect relatively small kicks and losses in real time but also can automatically apply SBP to control and minimize the influx size. These operational benefits can offset the cost of having the MPD kit aboard – an example of how “safety pays” – although HSE considerations are still the paramount objective.

It is important to distinguish RFC-HSE MPD from the MPD variants that have gained a reputation for drilling the “un-drillable” and received the greatest offshore attention to date. The CBHP variant of MPD necessitates maintaining a near-constant bottomhole pressure by manipulating SBP with flowrate and is utilized mainly in narrow margins of pore pressure and fracture or wellbore stability pressure.

RFC-HSE is the only variant that is practiced on otherwise conventional fluids programs. PMCD MPD requires drilling with sacrificial fluids (e.g., seawater) in severe to total loss zones. DGD MPD requires an artificial lift system (e.g., subsea mud lift pumps) or light fluids injection to avoid gross overbalance conditions in relatively depleted formations.

CBHP, PMCD and DGD all use the closed-loop system specifically for drilling purposes and usually only when conventional methods are not applicable for technical or economic reasons. RFC-HSE uses the closed-loop system to mitigate the risk of accidentally discharging drilling fluids into the environment and to enhance the safety of personnel during conventional operations. In addition, RFC-HSE is applicable to both shallow and deepwater wells where integrity of the primary well control barrier is of concern.

Globally, the opportunities for RFC-HSE MPD have been increasing. This results from advancements in RCD designs for offshore rigs and early kick-loss detection technology, as well as the increasing number of retrofitted and “MPD-ready” newbuild offshore rigs.

Furthermore, the newly revised Well Control Rule issued by the US Bureau of Safety and Environmental Enforcement (BSEE) seems to invite the application of RFC-HSE. BSEE’s revisions include the replacement of the term “static downhole mud weight” with “equivalent downhole mud weight” in regards to the required safe drilling margin, explaining that “the change from ‘static’ to ‘equivalent’ allows the downhole mud weight to be based on the mud properties that can be tested at the surface and then calculated to downhole conditions.”

Beyond the obvious benefits of drilling with a closed-loop system, a hallmark of RFC-HSE MPD is the ability to increase equivalent mud weight (EMW) with a modest application of SBP at first indication of well flow. Consequently, RFC-HSE MPD can potentially enable a greater number of prospects to be drilled while keeping with the intent of BSEE’s definition of safe drilling margin.

Compatible Equipment

The equipment needed for RFC-HSE MPD in marine environments is similar to that required onshore but adds the stipulations that a fit-for-purpose RCD must be suitable for the rig type being used, and the choke manifold system must be fully automated by a PLC. The resultant setup is essentially the same required for the CBHP variant.

The RFC-HSE MPD system not only can be used for kick-loss detection but can also continuously monitor the wellbore pressures and divert drilling and background gas safely to the appropriate systems. Mud weight returning from the well is monitored in real time and correlated to the associated drilling gas percentage. Connection gases could be routed to the mud/gas separator if deemed necessary.

Operational Benefits

Although RFC-HSE MPD primarily focuses on the safety of the circulating fluids process itself, a range of operational benefits contribute to recovering the cost of the MPD kit. RFC-HSE MPD enables a closed-loop system for diverting wellbore fluids away from the rig floor and applying SBP when needed. The system’s ability to detect flow in gallons rather than barrels and to compensate for floating rig movement helps to minimize false-positive kick alarms. RFC-HSE MPD also facilitates early kick-loss detection by providing precise mass flow in/out measurements in real time.

The ability to conduct dynamic FITs and LOTs whenever advisable enables drillers to verify and quantify pressure containment capability. Other noteworthy capabilities include:

• Real-time quantification of formation and fracture pressures during drilling operation;

• Wellbore ballooning upon regaining circulation and kicks from wellbore breathing;

• Circulating out an influx of known small volume using the automated choke control, as opposed to shutting in and circulating out manually;

• Wellbore monitoring during special operations such as tripping and cementing; and

• Managed pressure wellbore strengthening.

Controlling Wellbore Pressure Profile

Conventional drilling hydraulics – which remain virtually unchanged since Spindletop Field, circa 1901 – rely on hydrostatic mud weight as the primary well control barrier. In conventional drilling, secondary well control equipment (i.e., BOPs) is used to manage kicks and stop further intrusion of formation fluids into the wellbore. The influx is then circulated out of the wellbore using conventional methods. Mud weight is typically increased above the pore pressure to resume operations.

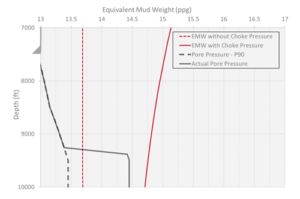

Figure 1 illustrates an increase in SBP as the choke reacts after detecting an influx. The corresponding increase in bottomhole pressure results in an increase of downhole EMW, illustrated in Figure 2, which demonstrates that the annular pressure profile can be swiftly manipulated to prevent further intrusion of an influx. Note that faster choke reaction times than those illustrated in these figures are possible depending on the specific well and system configuration. By enabling a swift response, SBP manipulation can effectively minimize influx size, compared with conventional well control. EMW with and without choke pressure lines represents equivalent mud weight at specific value of choke pressure.

Figure 3 illustrates an influx management matrix that defines the maximum SBP that the system can apply before the well is shut in. The maximum SBP is typically calculated separately for drilling and connection operations depending on wellbore integrity and surface pressure limitations. If permitted and approved by the contractor, operator and applicable regulatory bodies, the system can circulate a small-volume influx instead of shutting in the well. The small influx volume that can be safely circulated through the system is described in the influx management matrix.

After the influx has been circulated out, drilling can continue with increased mud weight in accordance with BSEE regulatory rules. Effective application of RFC-HSE can help minimize the impact of the pore pressure and fracture pressure uncertainty, which the new BSEE rule emphasizes. The RFC-HSE MPD system, therefore, augments the benefits of MPD technology, further enhancing the operator’s ability to comply with the safe drilling margin requirements from regulatory authorities.

Reducing False-Positive Kick Alarms

After several high-profile well control incidents in recent years, there has been a tendency to tighten kick alarms settings on offshore rigs. This practice has increased the frequency of false-positive kick alarms, resulting in unnecessary NPT, as well as increasing the risk of a real kick being interpreted as just another false alarm. A significant operational benefit of RFC-HSE MPD is its ability to reduce the frequency of false alarms, illustrated in Figure 4.

Summary

The availability of MPD-capable offshore drilling units is on the rise. The RFC-HSE variant of MPD is best suited for wells designed with open-to-atmosphere drilling systems. RFC-HSE MPD is intended not only to detect influx but also to apply SBP as needed to stop influx and minimize the influx size before the well is shut in. The RFC-HSE influx management matrix defines the maximum SBP that can be applied while the well is shut in. This effectively increases operational safety and protects personnel and assets.

RFC-HSE MPD may be considered one of the best and safest technologies for drilling in marine environments and offers economic benefits. As proven on thousands of land applications over the past two decades, the cost of drilling with a closed-loop system is often exceeded by the savings resulting from reduced NPT, lower risk of sidetracks and improved zonal isolation during well construction. DC