Shedding light on electrical simplicity

Standardizing, streamlining electrical power distribution systems reduces frequency of blackouts on deepwater rigs

By Diane Langley, editorial coordinator

Simpler power distribution systems are being cited as the reason for a reduction in blackout scenarios aboard deepwater rigs. According to Jorulf Nergard, vice president of sales for ABB, “Blackout situations have been improved with today’s solutions; things are different than 15 to 20 years ago when often more complicated configured electrical power-generation systems would get blackouts. The blackouts would occur without an understanding of the cause.”

A systems simplicity strategy is reflected in ABB’s “clean and lean” concept when it comes to deepwater rigs. “We’ve pushed this simplicity philosophy for five to six years now,” Mr Nergard said.

Isolated at sea, deepwater drillships and semisubmersibles rely on electrical power to perform every task. “Obviously, the power system is the crucial thing aboard a rig,” he continued. “Propulsion and drilling systems are now totally dependent on power from electrical sources.”

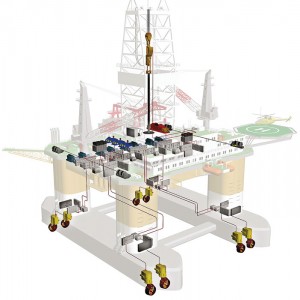

A power grid for a drillship is often split into three separate systems made up of two engines and generators with two azimuthing thrusters in each system. A grid for a semi typically has four separate systems with two engines and generators and two azimuthing thrusters in each system.

For the most part, standardized power-generation systems have replaced specific configurations that called for many crossovers and special arrangement and controls. “The market is emphasizing safe, reliable solutions that should be standard and proven reliable. In order to do that, simplicity is the key,” Mr Nergard commented.

“An area that is seeing more and more focus from operators and owners is to recover the electrical system faster than the typically two minutes when a blackout situation occurs and to recover the thrusters and drilling systems within 30 to 60 seconds. Although a blackout is unlikely to happen in a modern drilling rig installation, some additional measures to recover, such as ABB’s Fast Recovery After Blackout solution, must be in place to achieve this short recovery time,” he said.

“The ideal power-generation system is one that is designed to keep the vessel in her position and keep the operation running in the certified conditions, is reliable, is easy to maintain, and can operate with minimal losses. Low atmospheric emissions will be a big issue,” he said.

Electrical system designs now use industry-standard components adapted to marine requirements and focus on minimizing the risk that a single failure can shut down an entire rig.

“Our thinking is that a simplified design is easier to install, easier to operate and easier to maintain throughout the life of the vessel. And operational concerns in drilling rigs’ electrical systems are better addressed by adapting the performance of industry-standard products and systems, rather than engineering increasingly complex customized solutions,” Mr Nergard said.

As a result, equipment operators are finding the more standardized marine power systems easier to understand and operate, and onshore support personnel are better able to understand what is happening aboard the rig when remote assistance is needed.

As an example, ABB’s power systems have become more simplified for sixth-generation rigs, i.e., there is a straighter power line from the generated power and control voltage down to the thrusters and drilling system. There are not as many assignment systems and crossover connections as were used in previous generation rigs, he noted.

“Improvements have been made to control, maintain and protect the system,” Mr Nergard stated. System components have become more efficient, and fewer components are needed, resulting in reduced production costs and easier maintenance, e.g., sixth-generation rigs and ship systems are using switchboards and frequency drives with smaller dimensions. Protection relays and controls are using more microprocessors and can communicate on high-speed busses.

With these improvements, the sizes of the equipment rooms and numbers of cables are reduced; this is a cost element in shipyard construction. Hence, not only is there a reduced number of crossovers in the power-distribution systems, but the equipment itself is more efficient.

These changes are important because the higher number of parts, the higher likelihood for faults, Mr Nergard said. Advantages to the rig owner are reduced cost of installation and fewer components required but with a higher specification.

Cost is a driver of more compact systems. “We can produce it faster at a lower cost from us, the producer,” he said. “The safety aspect is another driver in that the more simple and efficient the system is, the more reliable it is.”

Solutions also exist to improve protection against the loss of diesel engines and generators; when one generator set has a control error, the diesel generator monitoring system can detect and disconnect the faulty generator set in a timely manner, traditionally hard to do. This type of error has been known to cause blackouts when power systems are connected. “We see this to be a more and more important solution,” Mr Nergard said.

Using a remote diagnostic system, all system parameters can be monitored from shore, and the availability for assistance is significantly improved. “This is easily available in today’s protection relays and control unit; communication on a high-speed communication bus will reduce the number of cable interfaces but increase information capacity,” he said.

A diesel electrical solution is normal for dynamically positioned (DP) vessels; flexibility is necessary to configure and vary the power from the power systems, particularly that of the thruster and drilling loads. “There are big variations when powering the thrusters; the variations range from very low power for long periods to the maximum possible for shorter periods. Redundancy requirements for DP are easier to meet; this flexibility also contributes to efficient operation,” he noted.

“When one is running few large engines and need only to feed small loads there will be an unnecessary big loss; it is better to run many small engines that can be disconnected according to the need,” Mr Nergard continued.

As a means to significantly improve losses, ABB developed a podded azimuthing thruster solution, the Azipod. This solution is in contrast to a mechanical thruster solution in which no gears and shaft drives are located between the motor and thruster, resulting in reduced losses. The CZ Azipod, introduced in 2001, has been shown to reduce losses by 10% to 20% compared with traditional mechanical azimuth thruster solutions.

Today’s sixth-generation rig power solutions also give less distortion to the electrical grid, caused by total harmonic distortion (THD) generated by the thruster and drilling frequency drives. Additional large filters are not needed; frequency drives are connected in a quasi 24 pulse configuration and keep the THD level well below the required 5%. This eliminates the need for space, circuit breakers and cables required for previous filters. The thruster and drilling frequency drive systems are also typically water cooled.

Present, future solutions

“The last generation of vessel solutions have been split up into DP/automation and electrical power systems,” Mr Nergard said. “We will probably see more autonomous solutions, for example thruster systems. I anticipate that some new solutions will surface in this area.”