‘Factory drilling’ boosts ROP with automation

4 drilling cells handled operations of 12 rigs on multiple directional wells onshore Mexico

By Ron Ayllon and Randy Hansen, Schlumberger

Recent developments in drilling automation processes and software systems have enabled dramatic improvements in rate of penetration (ROP). These systems have been used to optimize performance in the Chicontepec field development project onshore Mexico. Rig operations are being controlled from a facility in the nearby city of Poza Rica using a “factory drilling” concept that reduces the number of staff required on the rig and optimizes the benefits of available expertise.

Drilling optimization

Drilling operations represent a significant proportion of the cost of a well, so increasing ROP without detrimentally affecting hole quality or well placement saves time and money. Technological improvements help reduce the time and cost of developing fields and can enhance the production of hydrocarbons to surface, but these improvements can only be fully realized by optimizing the use of available drilling equipment and human expertise. Drilling optimization is the next step in the long-term evolution of the drilling process, leveraging gains made through mechanization and automation.

Drilling mechanization is an enabler for drilling automation, which makes drilling automation an enabler for drilling optimization.

Drilling mechanization developments have focused mainly on assisting limitations of human strength and reducing risk of physical harm on a rig. Elements include increased use of hydraulic, electric and pneumatic power, combined with reduced manual intervention with equipment and more remote operations. The mechanization of previously manual tasks has been successful in improving the safety of operations and has changed the profile and duties of a traditional drilling crew; however, it has had little impact on reducing the need for human intervention in the tasks required on a rig.

Drilling automation aims to reduce the impact of human behavior and risk of human error, with the goal of producing the same optimum result consistently, regardless of who is operating the equipment. The approach is similar to that taken by several other time- and safety-critical industries – such as aviation and petrochemical processing – that have acknowledged human limitations in managing repetitive or complex tasks and have turned to automation. The idea is not to eliminate the driller or drilling crews but rather to provide them with tools to enhance their performance.

Automation software

Schlumberger has developed a software tool based on a mathematical algorithm that uses real-time data to determine the combination of rotary speed (RPM) and weight-on-bit (WOB) as a function of the formation being drilled that will deliver the best ROP. The algorithm in the ROPO rate of penetration optimization is based on the modeled drilling response of a polycrystalline diamond compact (PDC) bit. Input data include surface and downhole measurements and parameters of the top drive, drill pipe, mud and bit. The algorithm computes RPM and WOB parameters that will deliver optimum ROP.

However, the parameter recommendations always stay within safe operating limits determined by the operator for the well being drilled.

The ROP optimizer can be configured to continually monitor and automatically control drilling parameters in a closed loop, to effectively “push the buttons” and drill without human intervention. In most applications to date, however, the software has been run in “advise mode,” where suggested changes to drilling parameters are made through human control. In wells drilled with mud motors, the drilling optimization automatic control is only effective when the drill string is turning – not when building angle in sliding mode. When used with rotary steerable systems, the software control is always active.

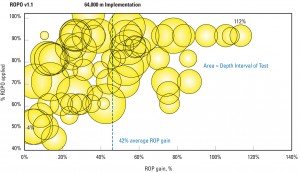

The algorithm has been tested in more than 200,000 ft of hole in more than 15 drilling operations around the world in both advise and control modes. It has been applied in hole sizes ranging from 6 ¾-in. to 16-in. and at all inclinations from vertical to horizontal. The system has consistently recommended parameter changes that improved ROP compared with either the driller’s performance in the same hole section with comparable lithology or the field average with a comparable bottomhole assembly.

In a well in Algeria, the system improved ROP up to 26% over the offset well average for the section. In Holland, it delivered increases in excess of 30%. Maximum benefit is realized when automation is implemented by means of the closed-loop system, whereby the set points for WOB and RPM are directly fed to the controls of the drilling rig equipment.

Schlumberger uses its RigPulse system to link the automation algorithms with the rig control system. This interface provides access to real-time rig data and enables two-way communication of key controls including WOB, flow rate and RPM. The automation routines have been run both at the well site and remotely. As long as there is sufficient reliable bandwidth, it does not matter where the programs are run. Typically, the operator setting up and overseeing the automation routines is located remotely; however, in all cases, the driller on the drill floor has complete control to engage or disengage from the automation system. The automation is designed around the human operator and not the other way around.

Factory drilling

Automation takes care of immediate repetitive processes at one rig site, but most large development projects have several rigs working in an area with similar environments and the same technical challenges. In high volume, multi-rig campaigns, achieving drilling optimization also requires optimizing the contribution from qualified human resources – leveraging their expertise and experience. The factory drilling concept addresses the frequent challenge of limited availability of reliable and experienced people to supervise operations.

The factory drilling approach is not suitable for all drilling projects, particularly those with a high level of uncertainty and where subsurface conditions are poorly understood. However, many development projects meet the required conditions:

• Multiple drilling rigs;

• High volume of wells per rig;

• Repeatable well design/well program; and

• Predictable downhole conditions with limited downhole risk.

Such environments foster a factory drilling process, enabled by seamless integration of services, multitasking of personnel and the use of fit-for-project rigs. The concept leverages the power of drilling optimization software and optimizes human expertise. It reduces cost and HSE exposure related to having personnel on the rig, so it has particular benefits for operations in remote areas.

Factory drilling requires close partnership between involved parties – including the drilling contractor, project manager and the operator.

Case history

The Schlumberger Integrated Project Management (IPM) group has been working with PEMEX since 2002 on its Chicontepec Project near Poza Rica, Mexico. This project is drilling multiple directional wells, each from multiple drilling pads using skid-mounted, fit-for-purpose rack and pinion and telescopic-double rigs from Saxon, a Schlumberger JV company. Rig count has fluctuated, and during 2009, it more than doubled to 17. Early in 2009, it became clear that the planned rapid increase would put a strain on available expertise, and a pilot plan was formed to move toward a factory drilling operations setup.

The first three factory drilling cells, handling three rigs each, were fully functional by June, and the fourth cell was fully functional by November 2009. The four factory drilling cells, running 24/7, are located next to one another in a Poza Rica office facility and are together handling 12 rigs. Each cell is equipped to monitor real-time data from each rig, control operations on each rig and communicate directly with each rig to discuss ongoing activities with a designated person on location, usually the drilling contractor’s rig manager. Each cell has a factory drilling supervisor, a senior well engineer, directional driller and well engineer.

The system has enabled significant reductions in personnel requirements, including eight well-site supervisors and 12 directional drillers, relative to what would be required to control 12 rigs from people all in the field.

The ROPO drilling optimization algorithm has been applied throughout the operations. Until recently, recommendations from the system were communicated to personnel on each rig for implementation. In May 2011, the first permanent installation of RigPulse running the ROPO service in closed-loop automation mode commenced on Saxon Rig 162. A second rig (Saxon Rig 163) started automated drilling afterward.

Preliminary results have been encouraging, with ROP increases greater than 25% in the 9 ½-in. and 6 ¾-in. hole sections. The ROP optimizer has maximum effect when running in “closed-loop” mode, as adjustments are made instantly and fine-tuned continuously. To date, it has delivered a 40% increase in on-bottom ROP relative to hundreds of previous wells in the area.

Field tests and commercial applications show that automated interpretation of drilling mechanics data can be used to control drilling parameters and improve performance. Automation will not replace drillers but should help them by performing the more mundane and repetitive tasks so that drillers can concentrate on the safety of the rig crew and the safe construction of the wellbore.

ROPO is a mark of Schlumberger.