Drilling & Completion Tech Digest

GE, Noble launch world’s first digital drilling vessel

GE and Noble Corp have launched the world’s first digital drilling vessel, targeted to achieve 20% operational expenditure reduction across the targeted equipment and improve drilling efficiency. The project aims to unlock the potential of digital solutions for offshore drilling operations.

The Digital Rig solution, powered by GE’s Predix platform and deployed on the Noble Globetrotter I drilling vessel, has been connected to all targeted control systems, including the drilling control network, the power management system and the dynamic positioning system. Data is collected through individual sensors and control systems, harmonized and centralized on the vessel before transmitting in near real time to GE’s Industrial Performance & Reliability Center for predictive analytics.

The delivered implementation and analytics on major marine and drilling equipment have already shown promising results, as the Digital Rig solution captured multiple anomalies and has produced alerts to inform potential failures up to two months before they would occur.

The Digital Rig solution combines data models from a digital replica of physical assets, or a digital twin, along with advanced analytics to detect off-standard behavior.

Through the learning curve, the digital twin will continue to enhance its predictive capability of machine behaviors and ultimately enable predictive maintenance. This means the personnel offshore can now focus their resources on maintenance activities that are truly needed and effective. The result is reduced unplanned downtime, improved revenue and significant maintenance cost savings.

Digital Rig is a mark of Noble.

Reveal Energy maps validate 2,500+ frac stages

Reveal Energy Services has validated more than 2,500 hydraulic fracturing stages throughout the US with its pressure-based fracture maps. The fracture maps show an operator the fracture half-length, height and asymmetry for validating the completion design on every well at a fraction of the cost of legacy diagnostic technologies, according to the company. The maps easily quantify this fracture geometry so operators will know whether a stimulation treatment is producing the planned fracture dimensions.

A pressure gauge and a bridge plug on a monitor well are required; hydraulic fracturing proceeds in the treatment well without downhole tools, downtime or additional crew.

A&M, WildHorse partner to research recovery of unconventional resources

The Texas A&M Engineering Experiment Station (TEES) is leading a research team to develop a new field laboratory in the Eagle Ford Shale. The team, along with WildHorse Resource Development Corp (WRD), has been awarded an $8 million grant from the US Department of Energy for research and development of unconventional oil and natural gas recovery. It will test next-generation monitoring solutions for hydraulic fracturing and enhanced oil recovery. The research team will be creating the Eagle Ford Shale Laboratory in Texas in collaboration with WRD, which will contribute three wells for testing – one existing well for re-fracturing and two new stimulation wells.

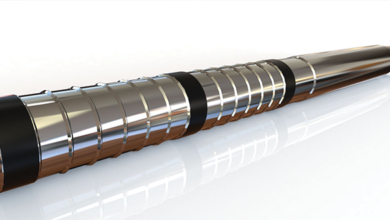

Wireless intelligent completions technology tested in Austria

Tendeka has completed field testing of its wireless intelligent completions technology, PulseEight. With funding support from the Oil & Gas Technology Center, Tendeka installed a PulseEight downhole device and a newly developed PulseEight surface system with OMV Group in Austria.

During the installation, various operations were undertaken to test the downhole device and prove the surface decoding system.

Accurate two-way wireless communication was demonstrated in a flowing gas well, and it was proven that the data and results could be shared over the cloud.

The system uses pressure pulse telemetry to channel wireless communication between a well’s downhole monitoring and control system and the wellhead.

Collaboration software enables single-trip casing exit in sakhalin well

Weatherford has announced the successful execution of a shallow-angle casing exit in Sakhalin Island, Russia, using the AccuView real-time remote support system. This marks the first deployment of the AccuView system in the Russian Federation. Weatherford used the AccuView system to transmit secure, real-time information between personnel on the platform rig and a global team of subject-matter experts.

The software system facilitated real-time analysis of foot-by-foot performance, which enabled the operator to complete the casing exit in a single trip. In the months leading up to the operation, Weatherford tested and verified all communications, including wired, wireless and satellite transmission capabilities, between the rig and operational support centers. Establishing a secure channel of communication was crucial in enabling real-time collaboration during the casing exit.

Globally, the AccuView system has been used to execute casing exits in more than 140 wells and has achieved a single-trip casing exit in all but one case. Weatherford anticipates further deployments of the AccuView system in Russia for various well construction and completion operations, including casing exits, fishing and liner-hanger installations.