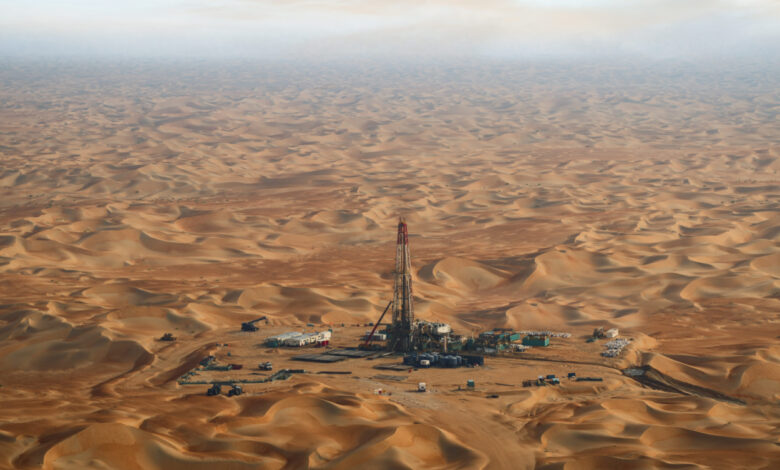

ADNOC Drilling looks to digital and integrated services solutions to drive better well deliveries

Automation, decarbonization and accelerated training programs among other key strategies to drive efficiencies, prepare for the future

By Stephen Whitfield, Senior Editor

By Stephen Whitfield, Senior Editor

Abdulrahman Abdulla AlSeiari is CEO of ADNOC Drilling.

What do you see as the biggest challenges that the global drilling industry currently faces?

With the current situation of the drilling business globally and in the Middle East, the biggest challenge is the availability of talent. It will be quite difficult for the industry to operate without new talent. The new energies are perhaps more attractive to them than coming into the drilling industry.

As industry leaders, we need to work on attracting talent in our direction. That may require us to show off some of the work we’re doing related to technology adoption, digitalization and other things that might resonate more with that talent.

What is ADNOC Drilling doing to attract new talent?

We have put a lot of investment into different kinds of programs that allow us to secure those people. For UAE nationals, we have dedicated programs for development where we’re targeting young people for positions within the organization. One of these programs is designed specifically for junior students, and they work full time as a derrickhand for a minimum of six months before they move on to another position. We train them in both theoretical and practical aspects of different positions on the rig, and we promote them to different positions over the course of two to three years. They’re assessed at each position, and we see where they fit.

We have another program for graduates where we develop their competencies until they’re good enough to become full-fledged drillers – that’s also a three-year program. We’re trying to capitalize on these individuals and push them faster up the ladder – not so fast where they don’t gain the knowledge, but fast enough. We’ve had guys come into our organization as roughnecks, and after going through this training, they’re in the position of a driller.

You mentioned showing off the work our industry is doing with technology and digitalization. Can you talk about some examples of ADNOC Drilling’s digital projects?

One example is our real-time monitoring center at our headquarters, where we see the performance of wells on a daily basis, and we can work with our clients to overcome any inefficiencies, or invisible lost time, using data. It’s a win-win for the drilling company and for the operator. We’re both benefitting from using that information. We’re also managing some of the oilfield service operations through the monitoring center. That has allowed us to reduce the number of people needed to be onsite because we put our subject matter experts in the center to monitor our operations.

These efforts have been focused primarily on directional drilling and geosteering, and this has helped us to realize substantial efficiency improvements.

Moving on to the subject of autonomy, what do you see as the key barriers to achieving fully autonomous drilling? Do you think that’s something we can realistically achieve?

I think it is something we can achieve, but we’re always going to require some integration with the human on the rig. When you’re drilling, not every hole is going to require the same method, and you have to interact with the well, deal with certain issues, troubleshoot in some areas.

When we talk about offshore, there are opportunities to automate certain processes. We’ve tried to do this on our jackups in the past where we automate certain activities. It worked, but somehow it was more inefficient than what we were doing before because of the processes we had to work through. Now, there are other technologies that we have to work with, particularly with moving pipe from the deck to the rig floor – that’s something we can look at. With our island rigs, we’ve done quite a lot of automation, and it’s been quite successful for us.

The biggest challenge for us has been with land rigs. We’ve found automation has been quite difficult for us to achieve there, simply because we keep changing locations every few weeks from one well to another. We have to dismantle the rig, move it to another location, assemble it again. We’ve found challenges with short circuits damaging some of the equipment on the rig – sometimes we’d have cables and fittings not going together, and then, say, the top drive would short circuit and that would cause NPT.

Nevertheless, I see there is a big opportunity when we’re talking about the whole process of drilling the well. I think it’s something we can work out, maybe get to a point where we can have a well drilled on autopilot but still have someone around just in case we need to interrupt the process or something goes wrong. That’s possible, and it doesn’t require major technology investment.

What are some of your main considerations when deciding whether to invest in a new digital/automation technology? Do you see that capital discipline and cost are holding the industry back from achieving more technical advances?

For us to invest in anything, we have to look at what we’re going to get out of it. What is the end result of the investment? We’re not just going to invest in something and not expect to get something out of it. Look at our investment in remote operations, which is something we can justify and which can make our clients happy. The payback is there. We definitely want to go for those types of investments. But it’s a case-by-case basis in terms of looking for opportunities for investment.

Beyond remote operations, one area where we’re really looking to invest is in decarbonization of the rig, especially the newbuilds. If I look at investing in electrification of the rig, there’s a direct benefit: We can stop burning diesel. There are two elements to that – one, the net-zero element, and two, we lower our fuel costs. Diesel is very expensive these days. Those are definitely things that attract us.

I know that ADNOC Drilling has already invested significantly in reducing its carbon footprint over the past few years. What further efforts can the world expect to see from your company in the next 2-5 years around ESG?

The major part for us is the engines that we use to operate the rig. Electrification will be a major solution for that. For the new rigs we have coming in, it’s much easier to incorporate the systems needed to electrify the rigs into the design from day one. For our existing rigs, there will be a lot of work required. Those are going to be focus areas for us.

Another area we’re looking at is the amount of waste that gets created in the drilling process. How can we manage that waste in a way that protects our environment? That could mean thermal treatment of the cuttings, reinjection of the cuttings or other different ways for us to look at that.

Right now, we have 30 mobile camps for treating wastewater, and because they’re working in remote locations, we have to use diesel engines to power them. We’re looking into using solar power for those camps. If that goes successfully, just imagine having all of those camps equipped with a solar system. On top of that, we’re working on battery energy storage systems for our land rigs. So, there’s a combination of several different technologies that we’ll continue to work on in the near future.

As we move forward, we’re going to see more activity. We’re going to target certain production capacities that have to be sustained. As that happens, the amount of ESG activity within our company is going to increase. We want to deliver 25% emissions reduction by 2030 and become net-zero by 2045. We have to deliver.

Let’s talk about the rigs some more. You’ve already spoken about electrification and low-carbon systems going on the rigs, but what upgrades to the rig are you considering in order to improve drilling efficiency in the near future?

To me, that is not just a question of efficiency. It’s about improving safety on the rig and protecting our people. We take safety as one of our major priorities – if there’s an area where we can invest that makes people safer, we will not hesitate. The tools that will make our rigs safer are also going to make them more efficient.

We’re looking at how we can better design our rigs to reduce the risks our personnel face, for example, with the management of loads. We’re looking at whether solutions related to digitalization can help. All of our rigs are equipped with CCTVs, and we’ve done a pilot with a computer vision system where you can identify unsafe situations on the rig, like if people aren’t wearing the right PPE. The system sounds an alarm to the driller so he can stop and deal with that. We’re shifting gears with that right now, so hopefully soon we will have a product that can generate additional value.

ADNOC Drilling began offering integrated drilling services in 2018. What drove that decision to step into this part of the drilling market? Has your work in the drilling services segment changed or enhanced the work you do as a rig contractor?

It has definitely helped us. What is every client concerned about? They want the well to be delivered safely, efficiently and cost effectively, and integrating services brings all of that together under one umbrella.

When you have lump sum contracts, you’re contracting with a company to bring the rig in, another company that does the directional drilling, and other companies in the process. Everybody wants to hit their targets, and these targets may differ a little bit, so you’re going to see some inefficiencies. But when you have integrated solutions under one umbrella and one leader, you have synergy. You can ensure everyone’s on the same page.

Now, drilling companies are in charge of the safety of everyone else out there on the rig. Whether that’s the driller’s personnel or third-party service company personnel, it’s all the responsibility of the drilling company. To us, offering integrated services improves those efficiencies. That’s why our market share has been increasing continuously. Today, we offer integrated services for around 45-50% of our fleet. We’re targeting 55-60% within the next two years.

We’ve managed to demonstrate the efficiency of integrated services to our clients, resulting in savings of around $300 million since we started the program. So, we’re satisfied, although we’re still looking to improve. We’re looking at increasing the local manufacturing of some of our drilling fluids, for instance.

We see this integrated offering as complementary to our drilling business. I’ve worked on the driller side and the operator side, and I think both sides need to work hand in hand to deliver the well. That’s why I’ve been very much pushing for us to develop this integrated solution.

ADNOC Drilling also handles well completions, which are normally not part of a drilling contractor’s expertise. What is your company working on to improve completions efficiency in the coming few years

There’s a lot that can be done in the completion cycle, provided that we get the right technologies. I’ll give you an example on the unconventional side. We’ve been seeing a lot of unconventional activity in the US, Canada and even China, and there’s a learning curve with the technologies that they’ve gone through, a lot of new technologies they have introduced into the process.

For us, the question is how can we bring those learnings into the system and shorten this learning curve? I don’t need to start at step one. I can jump-start from where they are and take the lessons they’ve learned in those regions. There are a lot of good technologies that can be introduced for completions that we’ll be working on.

In late 2021, ADNOC Drilling announced an alliance with Helmerich & Payne (H&P). Can you talk about any lessons you might’ve gained from this collaboration so far and what value has been generated?

H&P is well-known for their work in the unconventional space. They came in as partners, and we’ve purchased eight rigs from them so far – we’re probably one of the first companies to own our own H&P FlexRigs. All of those rigs are operational and running very smoothly. We both see value in each other, and we both want to take this partnership to the next level. Definitely, there is more we can work with, and we will do what we can to make this partnership even more successful. DC